Process data

Measuring task:

Flow velocity measurement for process regulation and monitoring quality in the hardening bath

Measuring point:

At the heat conducting plates in the quenching basin

Measuring range:

Typically 0.2 … 2 m/s in two directions

Process pressure:

Hydrostatic pressure depending on insertion depth

Process environment

80 … 130 °C

Your advantage

Flexible

For measurements in oil and water hardening baths vertically or horizontally. Sensors can be used as fixed or portable installations.

Economical

Measuring data can be transferred directly to process control. If portable measurement is needed, measuring data can be saved in the handheld unit for evaluation at a computer.

Tried and tested

The automotive infustry and its suppliers use our vane wheel sensors for this application

Application

Quenching is an important step in heat treatment of metallic materials like motoric components, machines or gears to target certain hardness grades and hardening depths in the material. Usually quenching happens through immersion in a quenching basin.

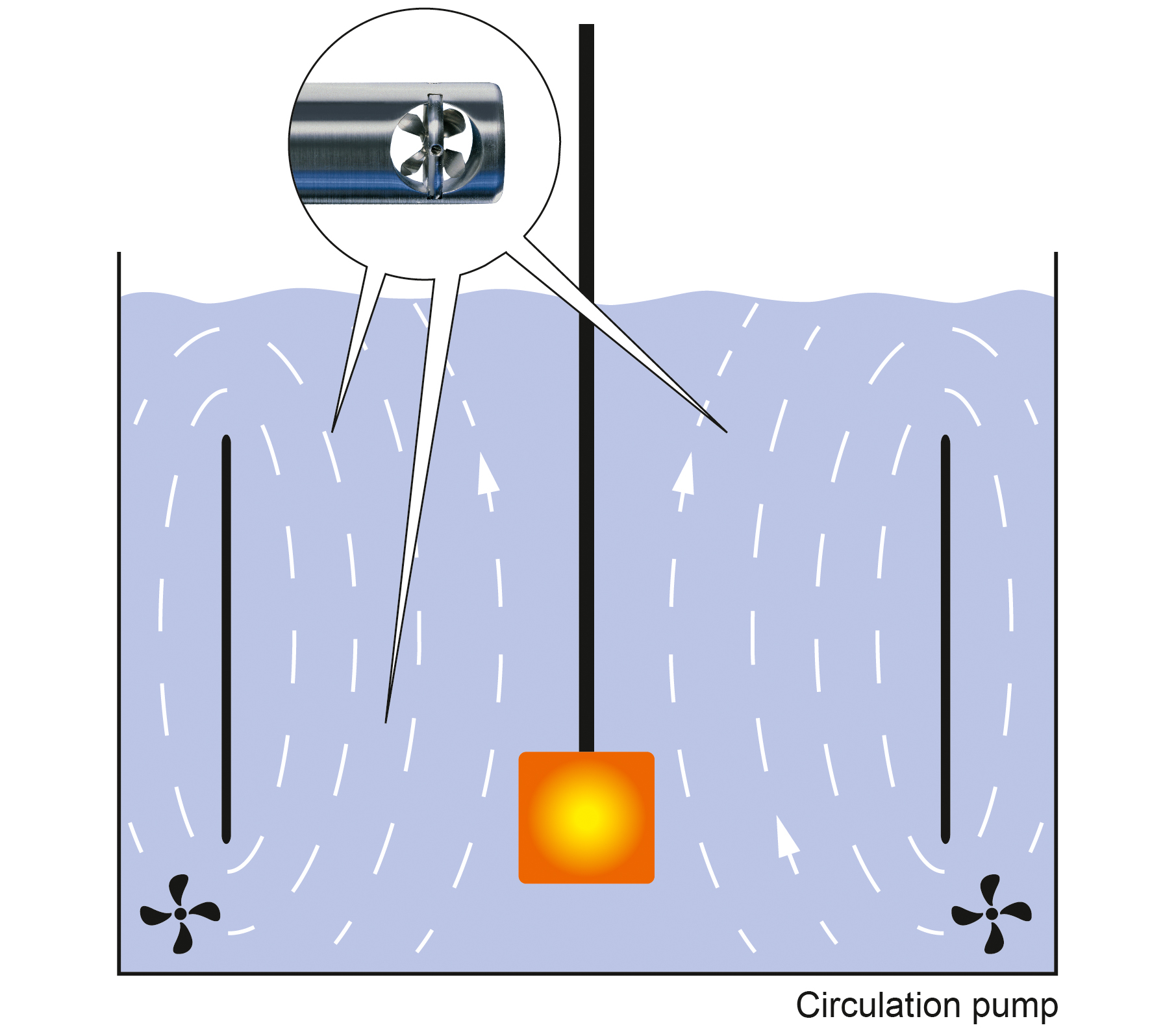

Different quenching media are used depending on the task. It’s important that the entire element is evenly surrounded by flowing liquid. There are circulating pumps in the quenching basins that move the quenching medium and therefore provide an even heat distribution. Baffles in the heating bath support the process. Special sensors measure flow in the quenching basin. It’s an importan process parameter and therefore a quality factor.

Höntzsch has been delivering vane wheel flow sensors for many years to engine manufacturers in the automotive industry and many more. The sensors play an important role in wear resistance especially with drive technology.

Recommended products

Vane wheel ZS25 … ZG1

Handheld unit flowtherm NT.2