Process data

Measuring task:

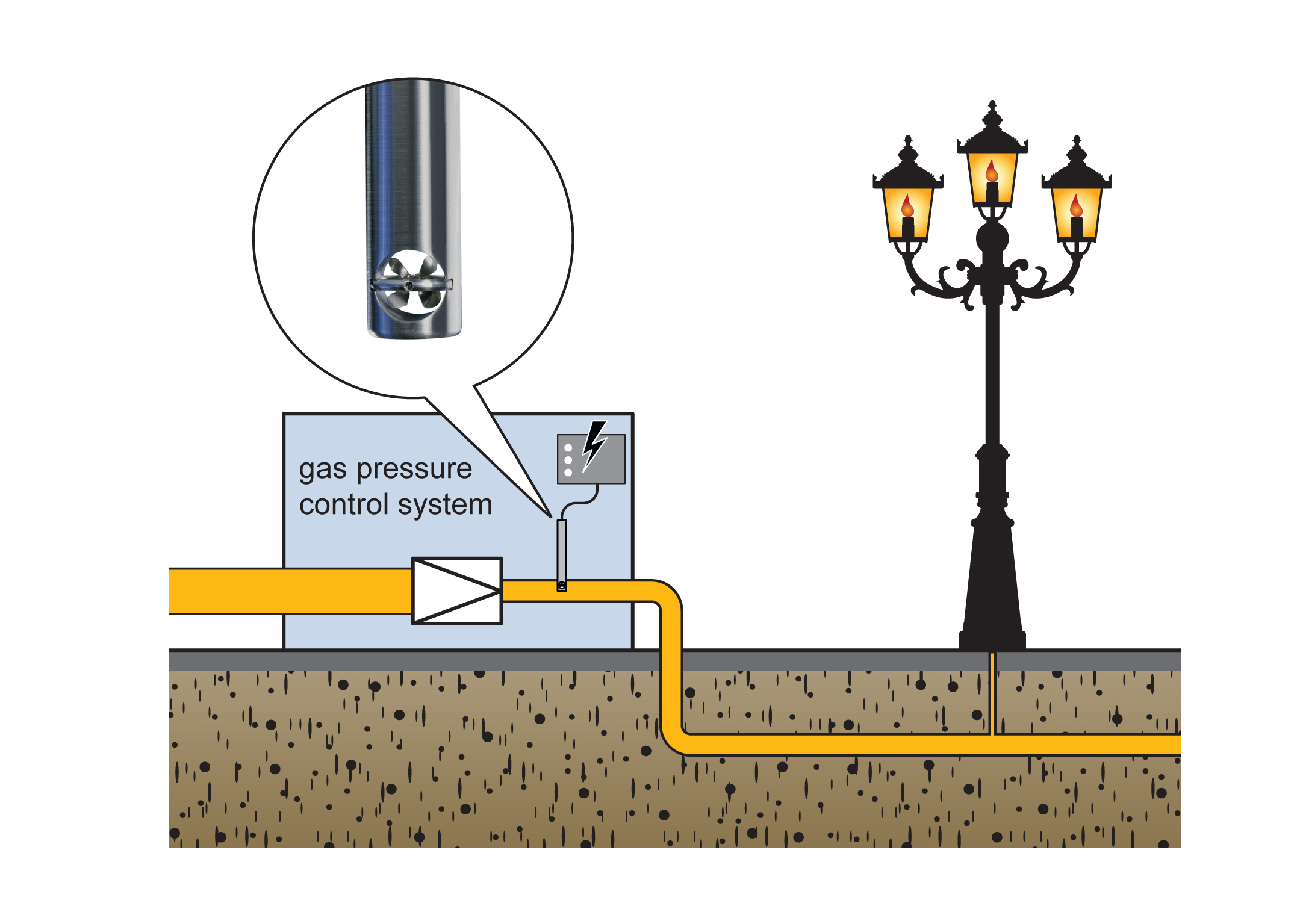

Flow rate from supplying gas lights to street lights

Measuring point:

Gas pressure regulation station

Measuring range:

Up to 1,000 m³/h

Process pressure:

Ca. 40 mbar

Process environment:

+5 … 40 °C

Application

The streets in Düsseldorf are illuminated with electrical lights and gas lights. Each gas light’s supply comes from gas pipes from gas pressure throttling stations. The lights are ignited by a defined pressure surge which has a defined pressure level and flow rate. This flow rate can be measured and monitored with Höntzsch measuring instruments. It’s the only way to guarantee a safe ignition process.

Your advantage

Tried and tested

Since 2006 Höntzsch vane wheel sensors type ZS25 have been used in this application

Precise

The sensor’s very low measuring uncertainty ensures reliable set-up of the gas lights and therefore the lighting.

Aesthetics

The used measuring technology also contributes to the preservation of the historical cityscape with gas lights.

Recommended products

Vane wheel ZS25 ZG2

Product Product data sheet

With isolation / supply unit and separate evaluation unit