Process data

Measuring task:

Flow velocity for process regulation

Measuring point:

In the area of laminar flow below the ceiling filter (plenum)

In the exhaust duct

Measuring range:

Laminar: 0.25 … 0.5 m/s

Exhaust air: 15 … 25 m/s

Process pressure:

Atmospheric

Process environment:

20 … 200 °C

Recommended products

Application

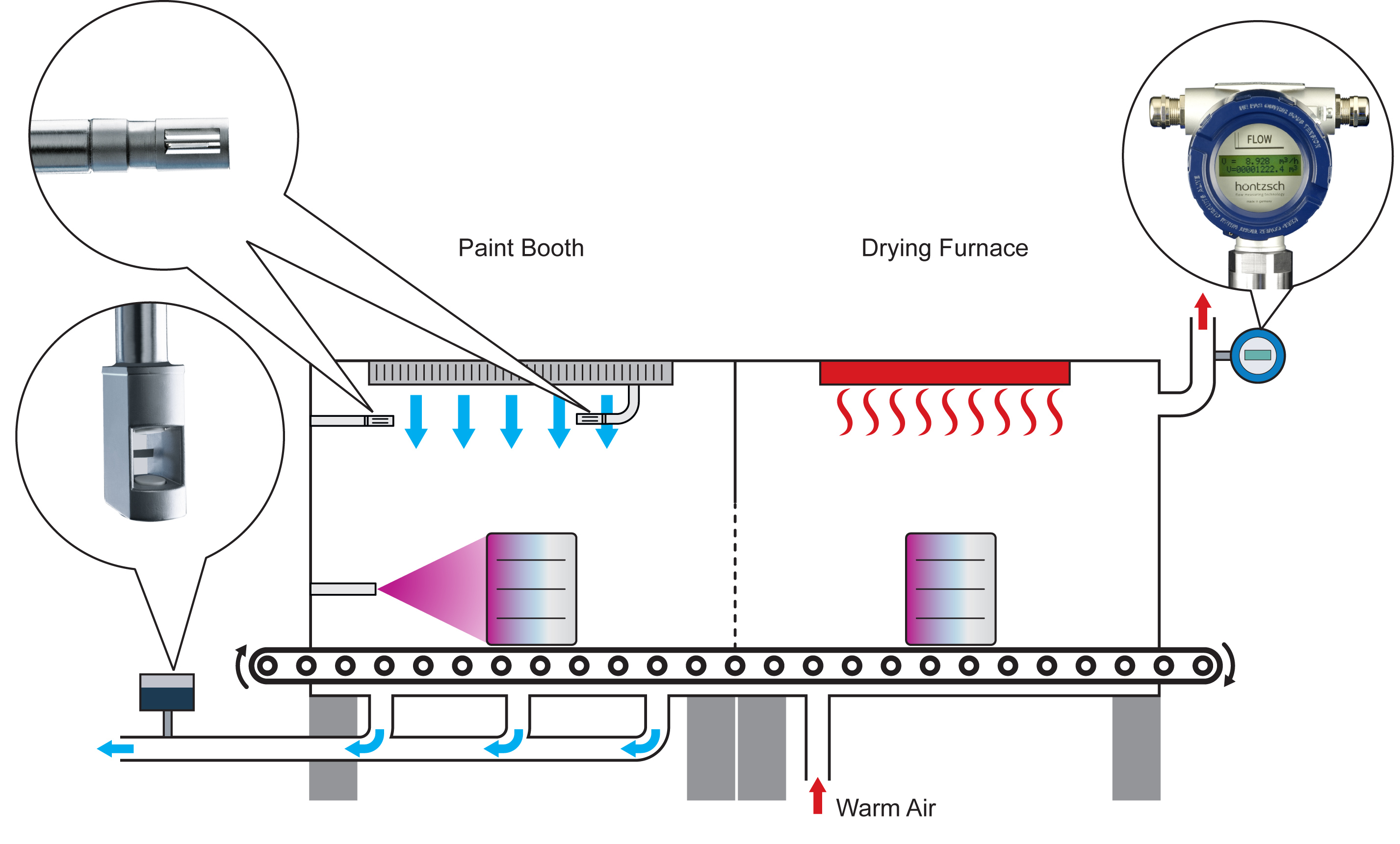

In coating facilities flow velocity needs to be measured accurately at different points. Laminar flow has to be ensured in the spray booth to get optimal results and the exhaust air in the coating booth and the chamber kiln have to be monitored for safety and environmental reasons.

To achieve optimal coating results there have to be specific room conditions. Temperature, humidity and air flow have to be kept withing a strict range. Besides room conditions, environmental protection in coating and spraying also plays a major role. The resulting overspray in the spray booth is diverted by a regulated, downward-directed air flow. Said air flow is collected, measured and processed. The exhaust air of the chamber kilns is also measured. That way environmental pollution is reduced. It also ensures that no harmful or flammable concentrations of solvents arise.

Your advantage

Secures your process

The TA10 secures the coating process according to current regulations

Better safe than sorry:

Flow sensors are also available in an ex-version and with SIL certificate

Reference of the market leader

The leading manufacturer for coating facilities uses our sensors