Applications & Industries

Industries

Höntzsch Measuring Technology: at home in many lines of business

Pharma Industry

The implementation of quality system guidelines according to Good Manufacturing Practice (GMP) ensures that safety, quality and effectiveness in all stages of production are guaranteed. Höntzsch sensors make a considerable contribution: be it in research, production, packaging or application testing of pharmaceutical products.

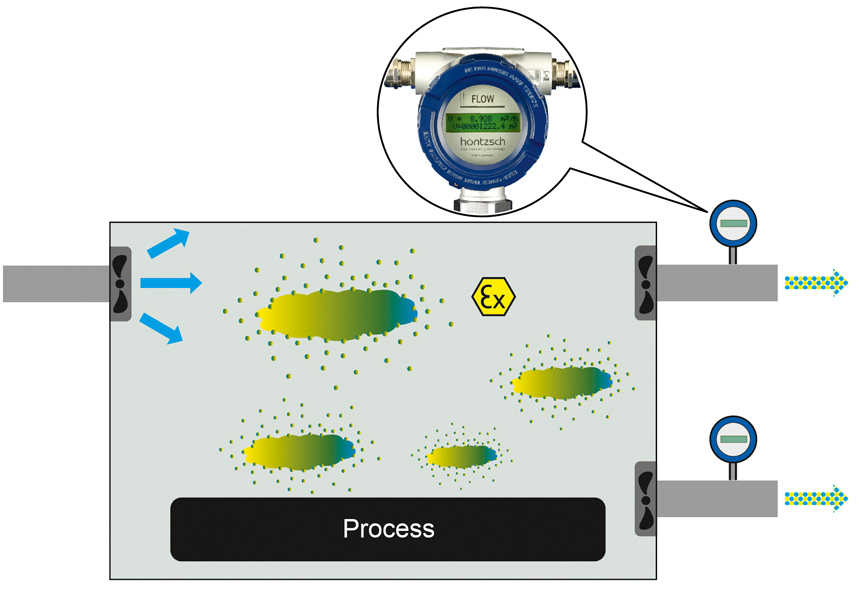

Chemical Industry

Höntzsch instruments with ATEX and SIL certification guarantee plant safety, product quality and efficient energy use. They have proved successful in both fixed and portable applications in aggressive and explosive process gases, flare and waste gases.

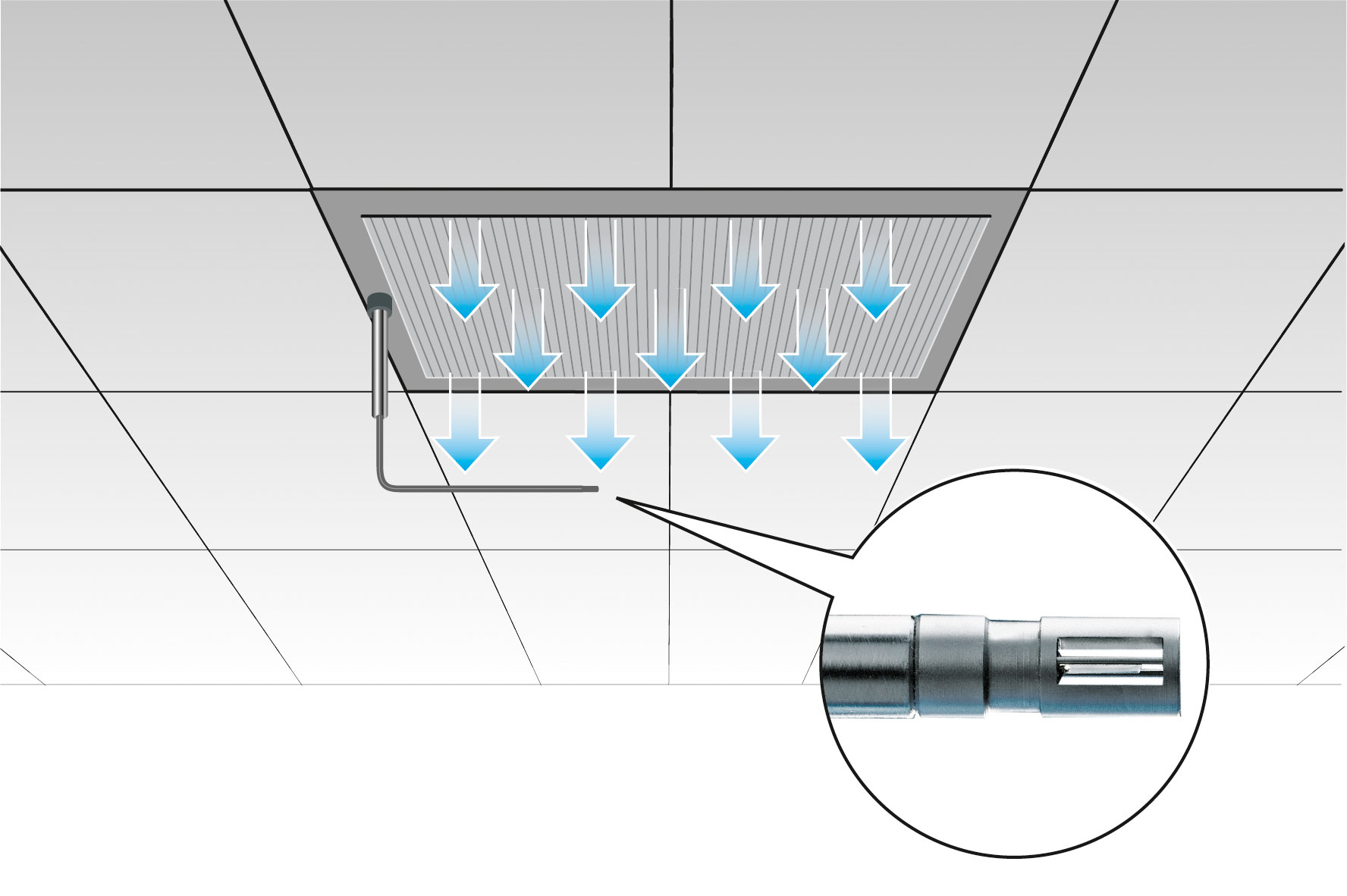

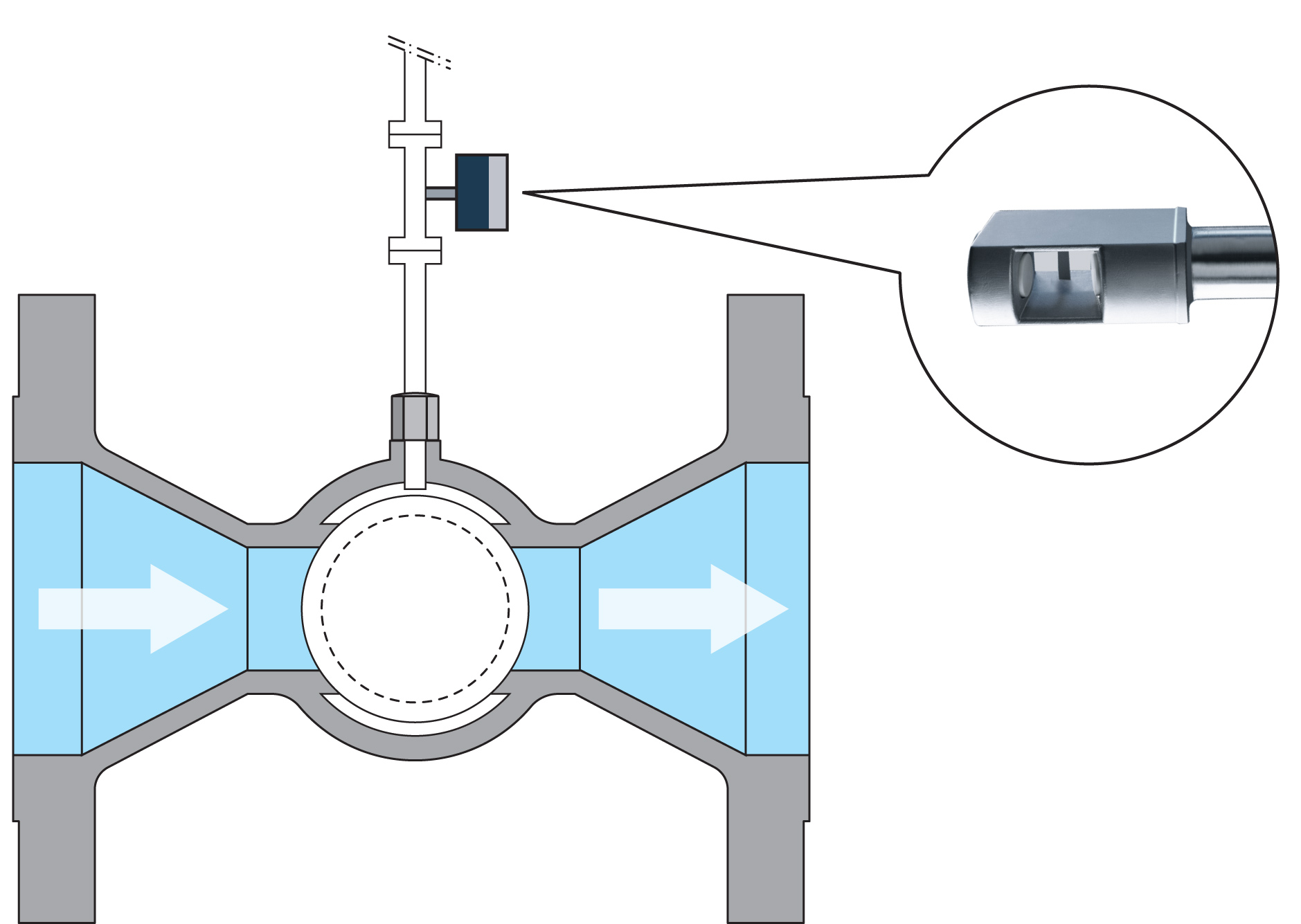

Cleanroom Technology

To ensure air quality in clean rooms, a laminar flow must be generated. This can only succeed, if the flow velocity is constantly controlled in a very small range. Thermal sensors TA10 with integrated shaft transducer are predestined for this type of application. Vane wheel sensors ZS30 are the optimal solution for laminar flow in temperatures up to 350 °C.

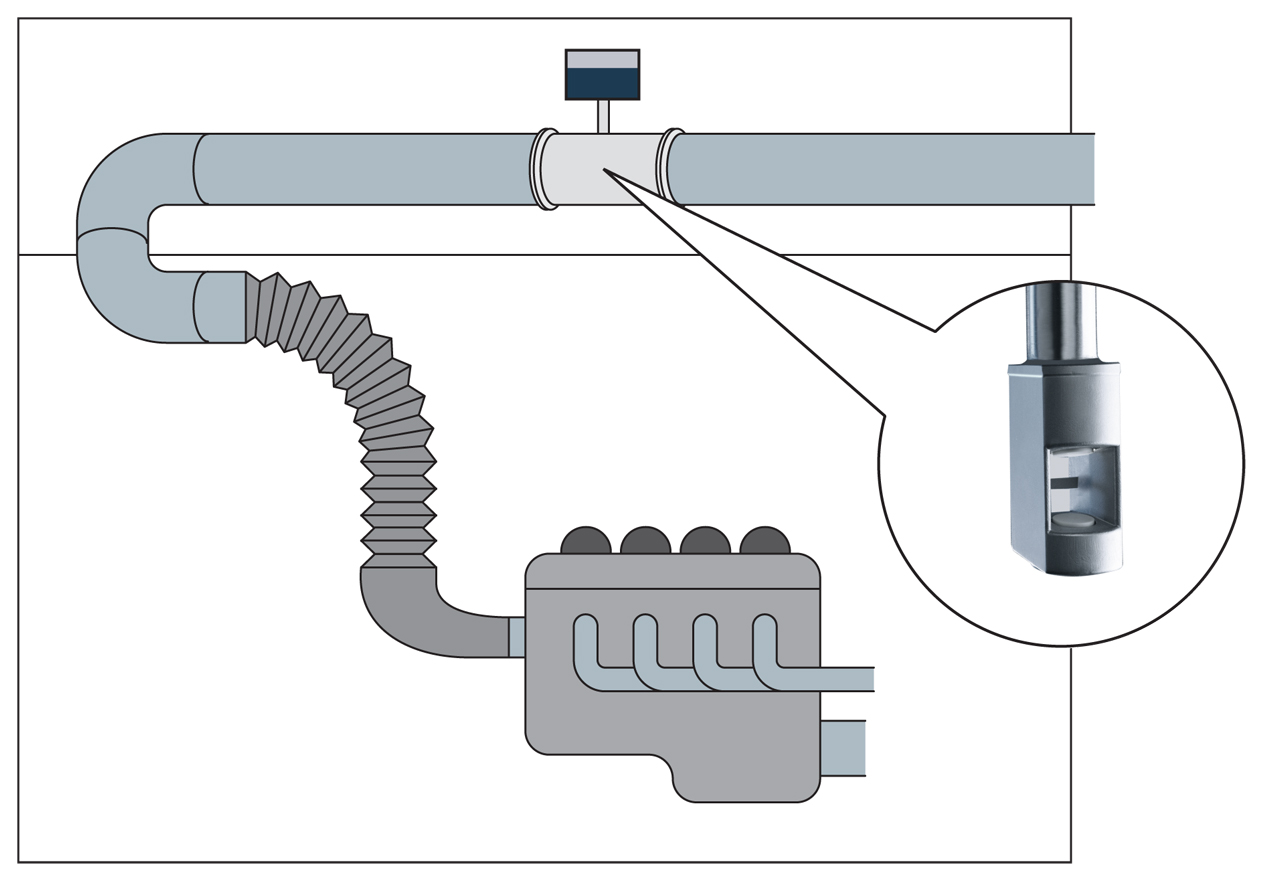

Engine Test Bench Technology

Ever decreasing emission limit values and pressure to realise fuel saving potential, make accurate detection of all relevant parameters in test bench measuring necessary at all times. Höntzsch sensors deliver precise values with long-term stability when measuring the mass flow of engine intake air or exhaust gas.

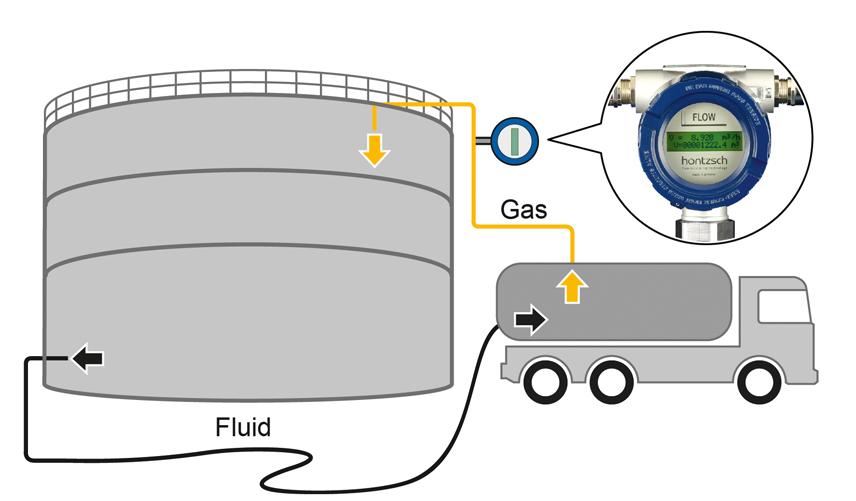

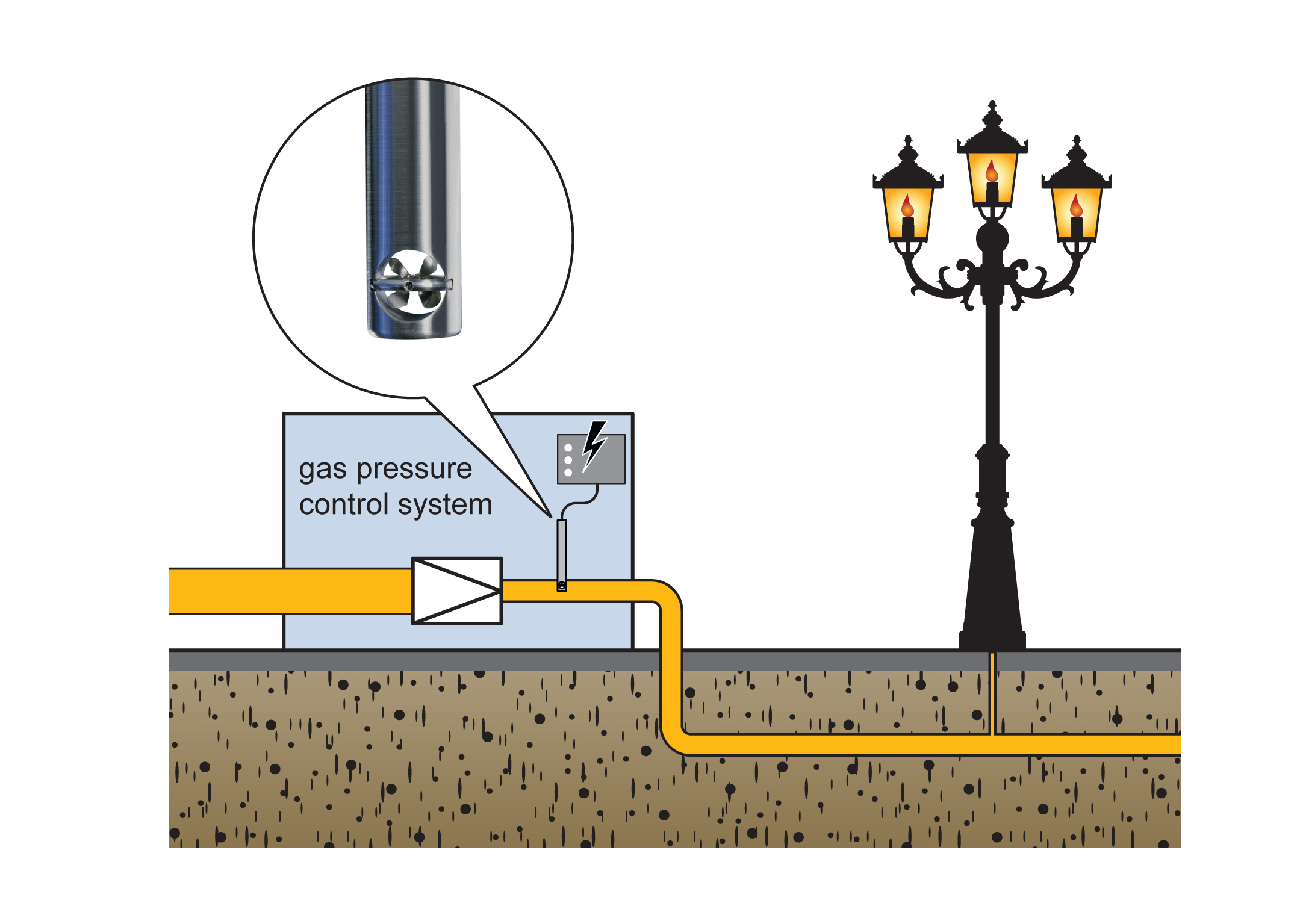

Gas Utilities

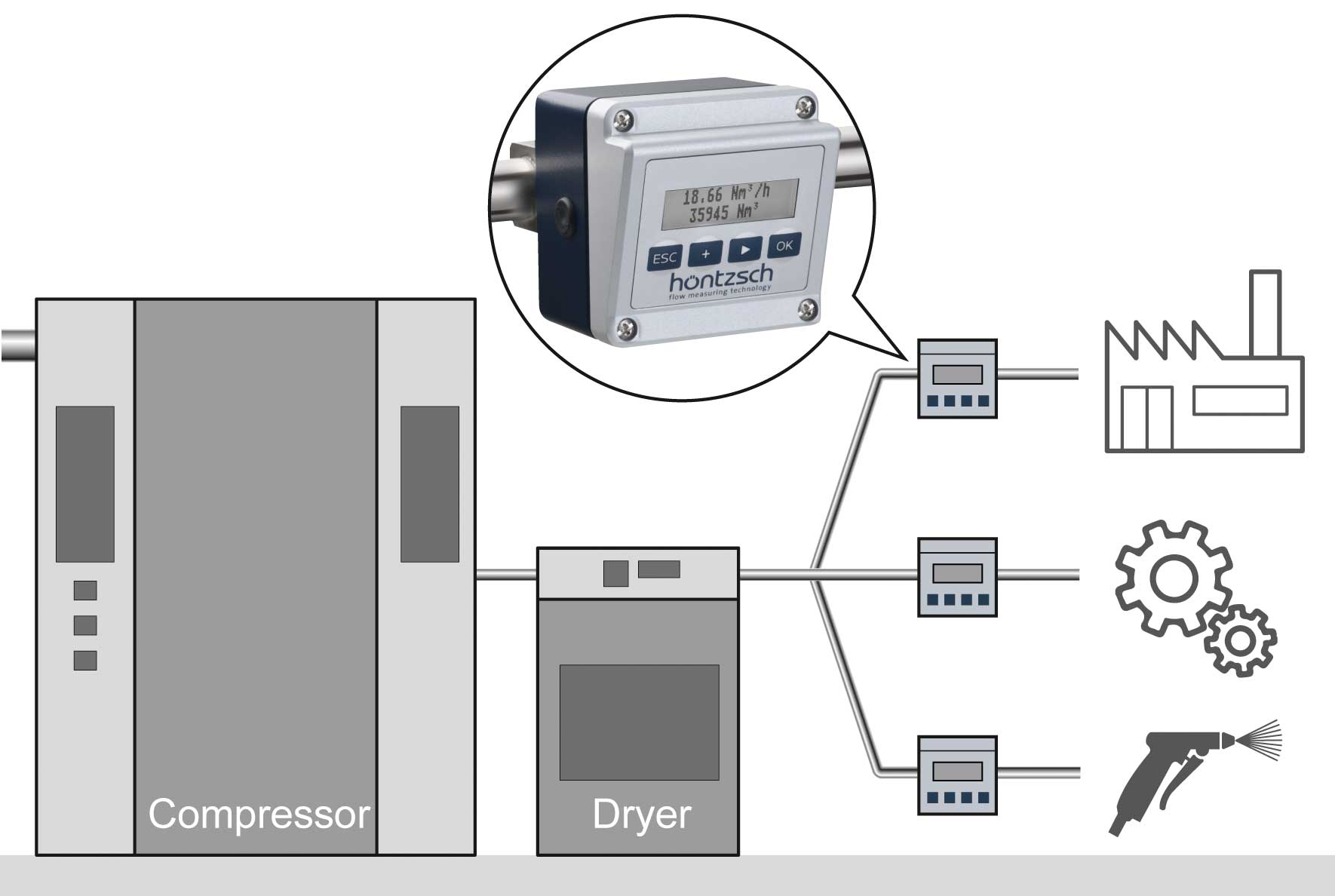

Compressed air, natural gas and other gas mediums are expensive sources of energy. Considerable cost savings can be achieved by detecting and eliminating pipe leakages and performance control of compressors. Thermal flow sensors TA have no moving parts, are accurate, robust and maintenance-free. With their turndown ratio of 1 : 1000 flow rates from leakage flows to maximal withdrawal of gas can be measured reliably.

Gas ejection blowers in natural gas pipelines

measurement of compressed air consumption

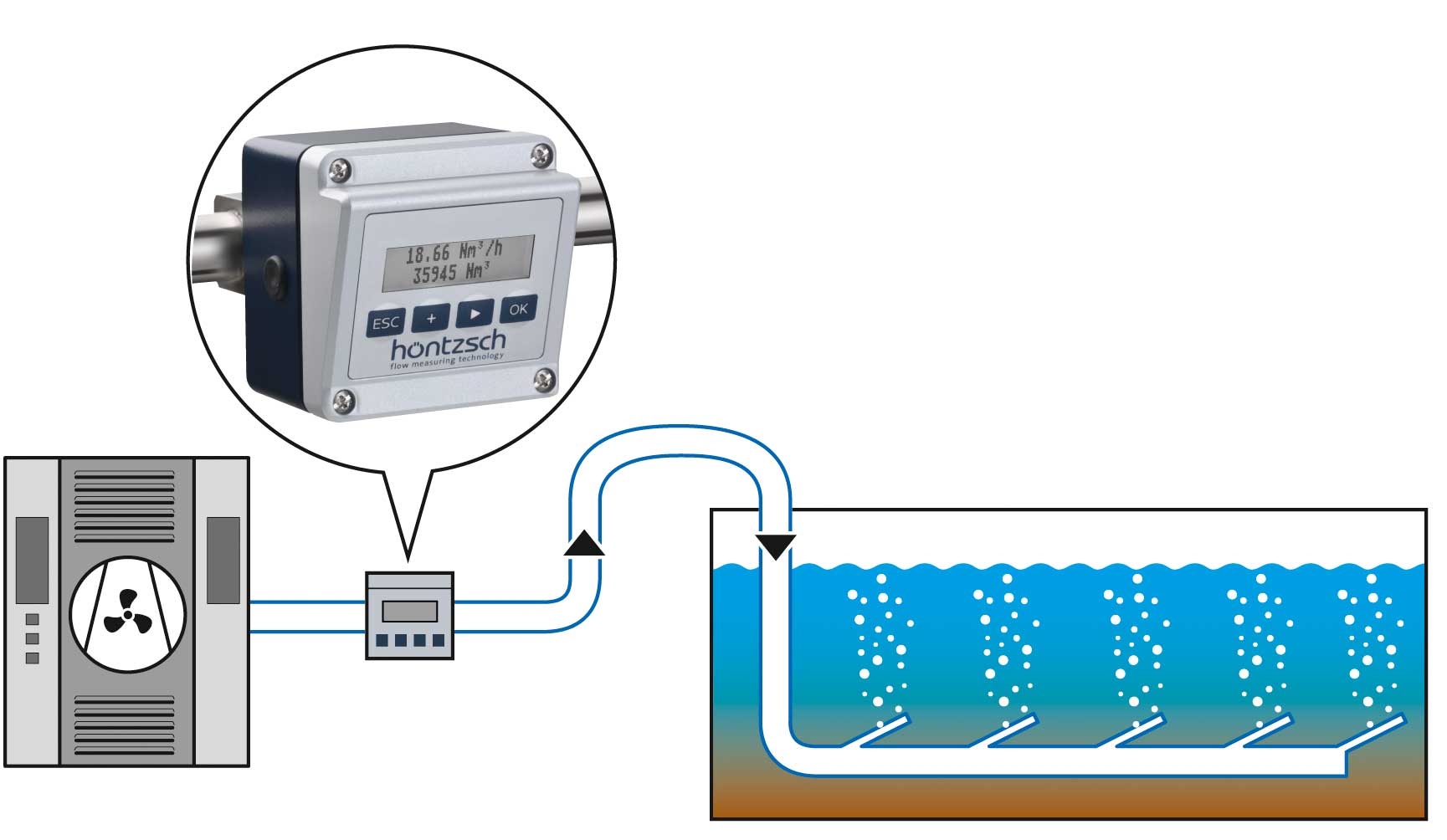

Water Management

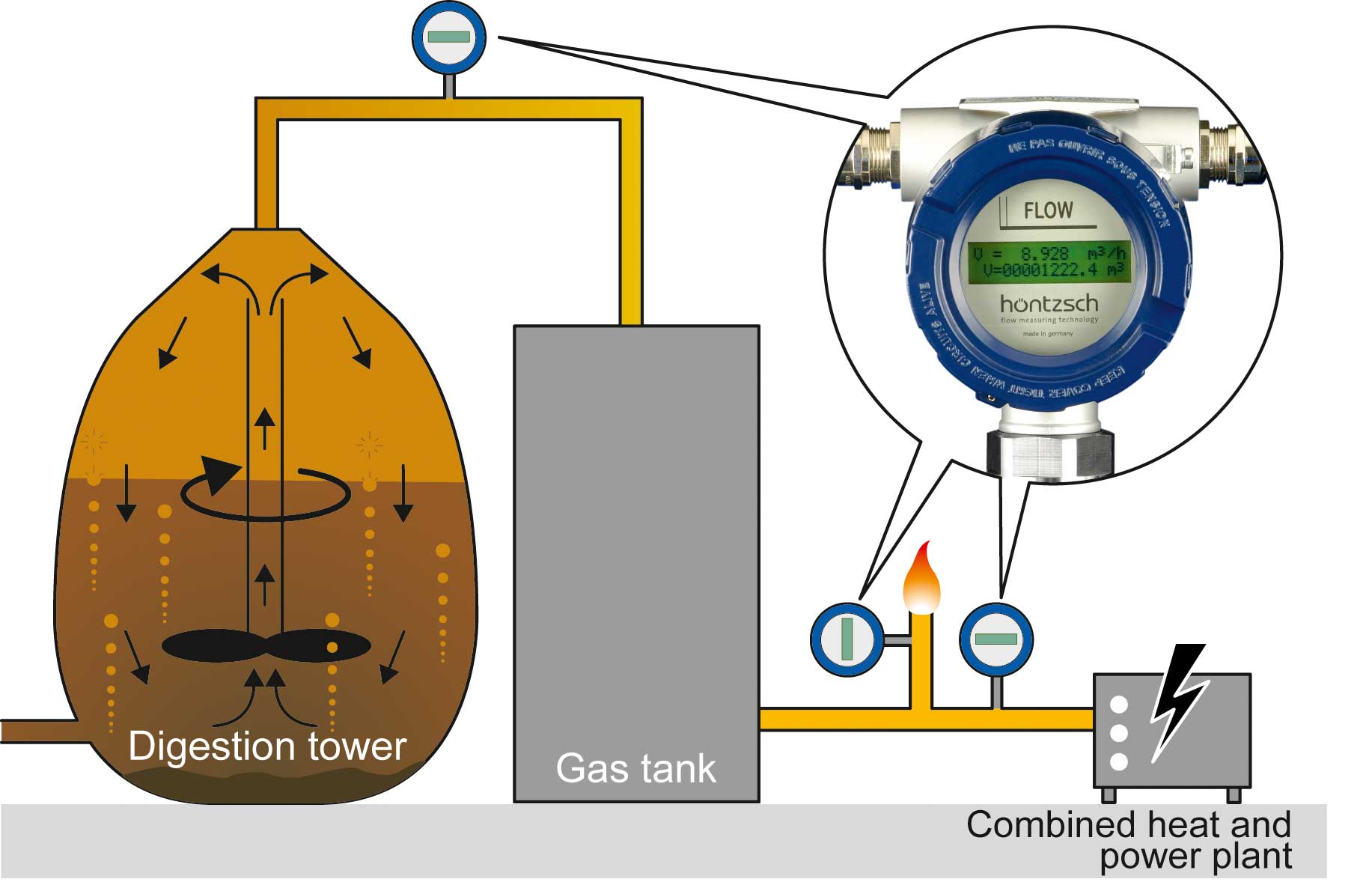

Air supply in aeration basins is extremely cost-intensive. By optimising the compressor control, which relies on accurate flow rate measuring with Höntzsch TA or VA sensors, ample savings potential can be freed-up. For monitoring the amount of gas produced in the digestion tower, maintenance-free, explosion-proof vortex sensors VA are strongly recommended.

Sewage / biogas quantity measurement in wastewater treatment

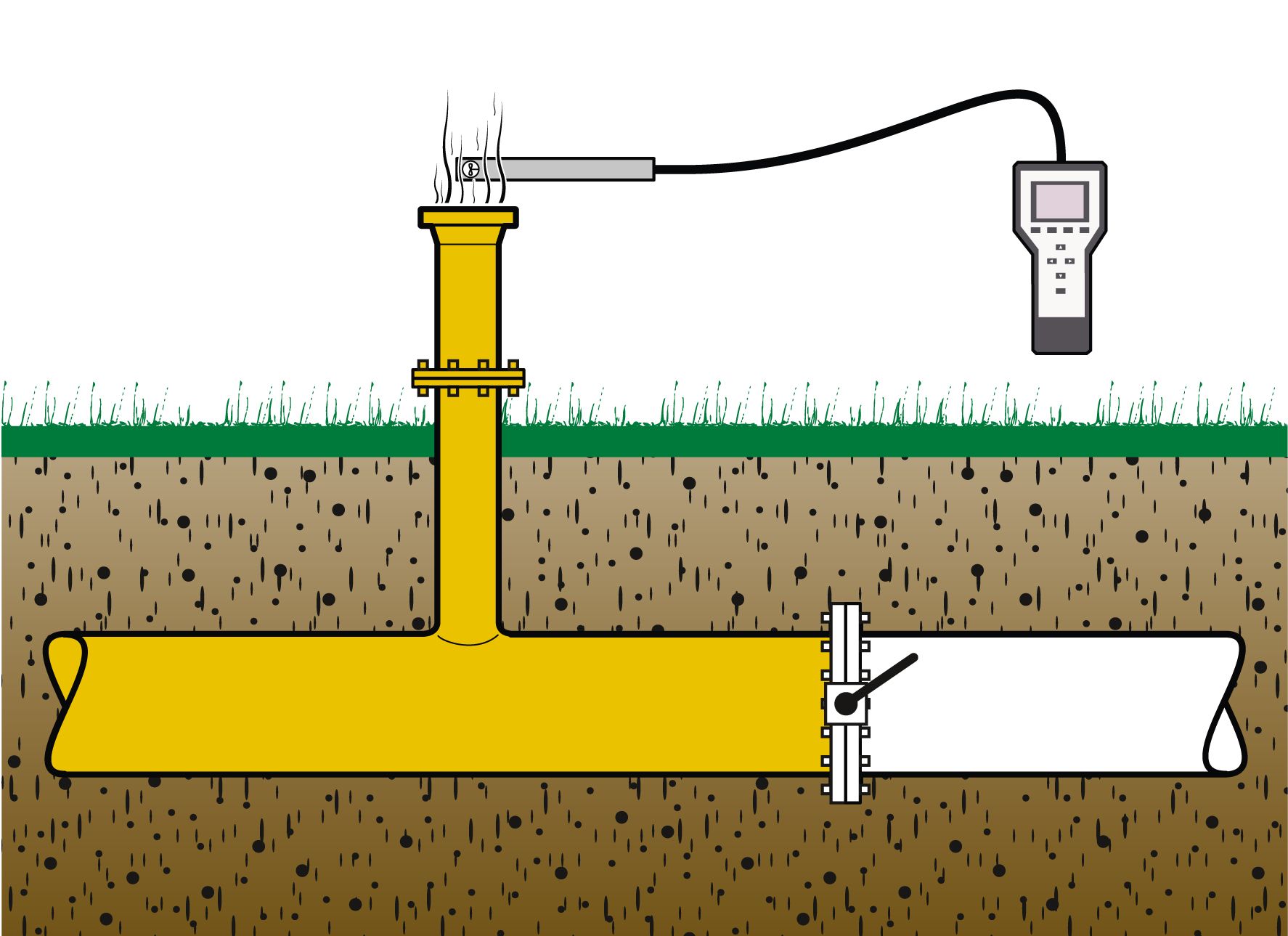

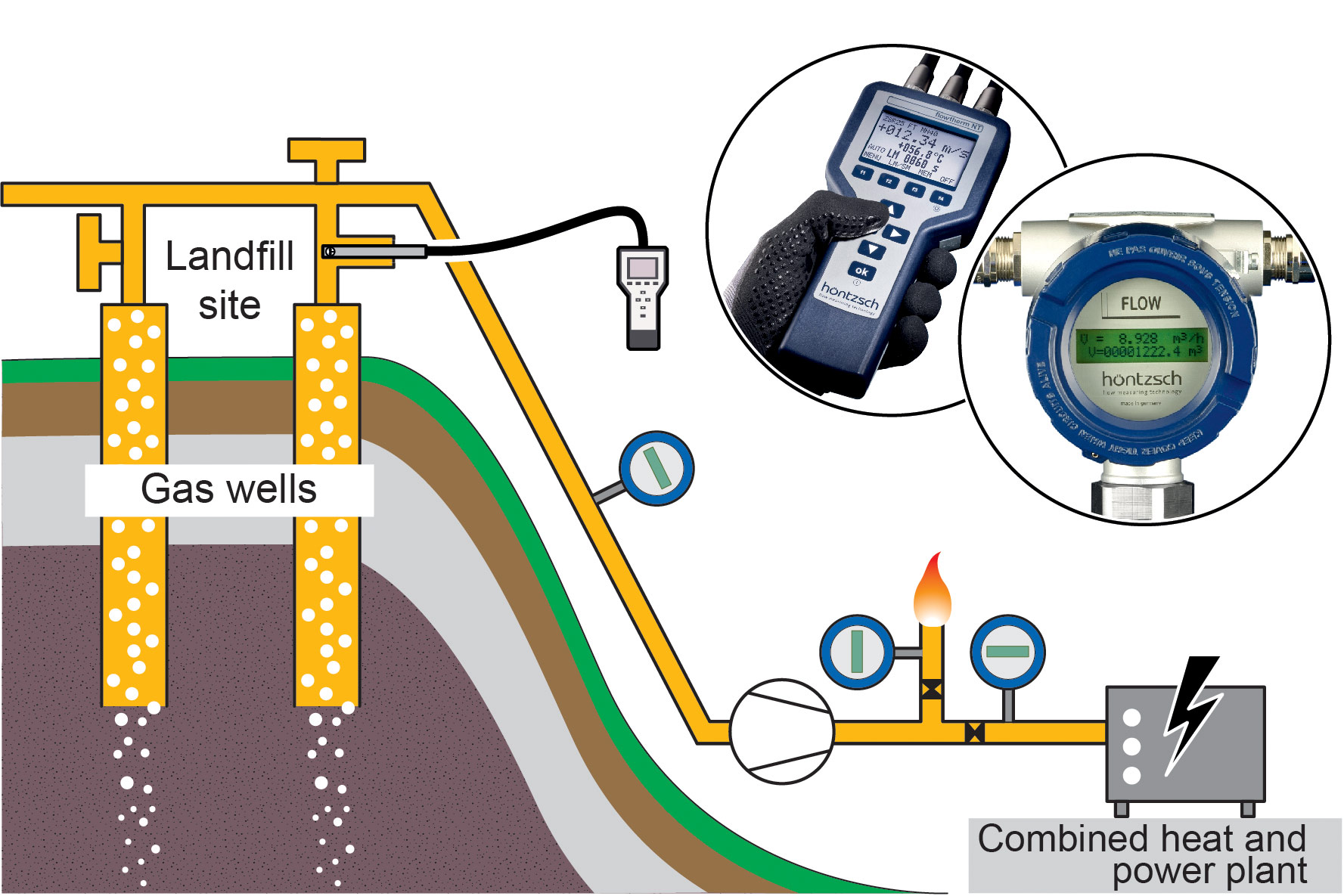

Landfill Technology

Explosion-proof thermal flow sensors TA have proved their worth in fixed and portable measuring of landfill gas amounts. These also reliably measure the ever-decreasing gas flow rate on completed landfill sites.

Nuclear Power Plants

Safety requirements in nuclear power plants have top priority. Höntzsch sensors in various measuring methods are used in monitoring numerous process controls. Measuring signals are indispensable for the evaluation assessment of operating conditions.

Biogas Generation

Höntzsch vortex sensors for explosive atmospheres (ATEX), which generate just a marginal pressure drop, are recommended for measuring the flow rate of biogas. The results are reliable, even if the flow rate is low, if the gas composition changes or if the gas is wet or charged with particles.

Aerodynamics

Vane wheel flow sensors TS are still able to deliver precise values under difficult oncoming flow conditions, even if the alignment to flow is not optimal. In wind tunnel or road tests the flow field can be determined extremely quickly even around complex structures. Through the ability to sense the +/- flow direction, reliable values are still possible even in backflow on motorcar radiators.

Traffic Tunnels, Mining Galleries, Waste Disposal Sites

Höntzsch TwinPipe vortex flow sensors with +/-directional sensing are highly suitable for measuring the flow velocity in traffic tunnels, mining galleries and waste disposal sites as well as for measuring in ventilation control.

Thanks to their high fatigue strength and long-term stability, these sensors are reliable and precise, even in emergency applications.

Aerospace

By way of example, when measuring the airflow around actuators in the wings of commercial aircraft, cabin flow or weight-optimised flow rate measurement of life support systems in crewed spaceflight: Höntzsch has the customised solution!

More applications in different industries:

Measurements of air exchange in forced-ventilated rooms

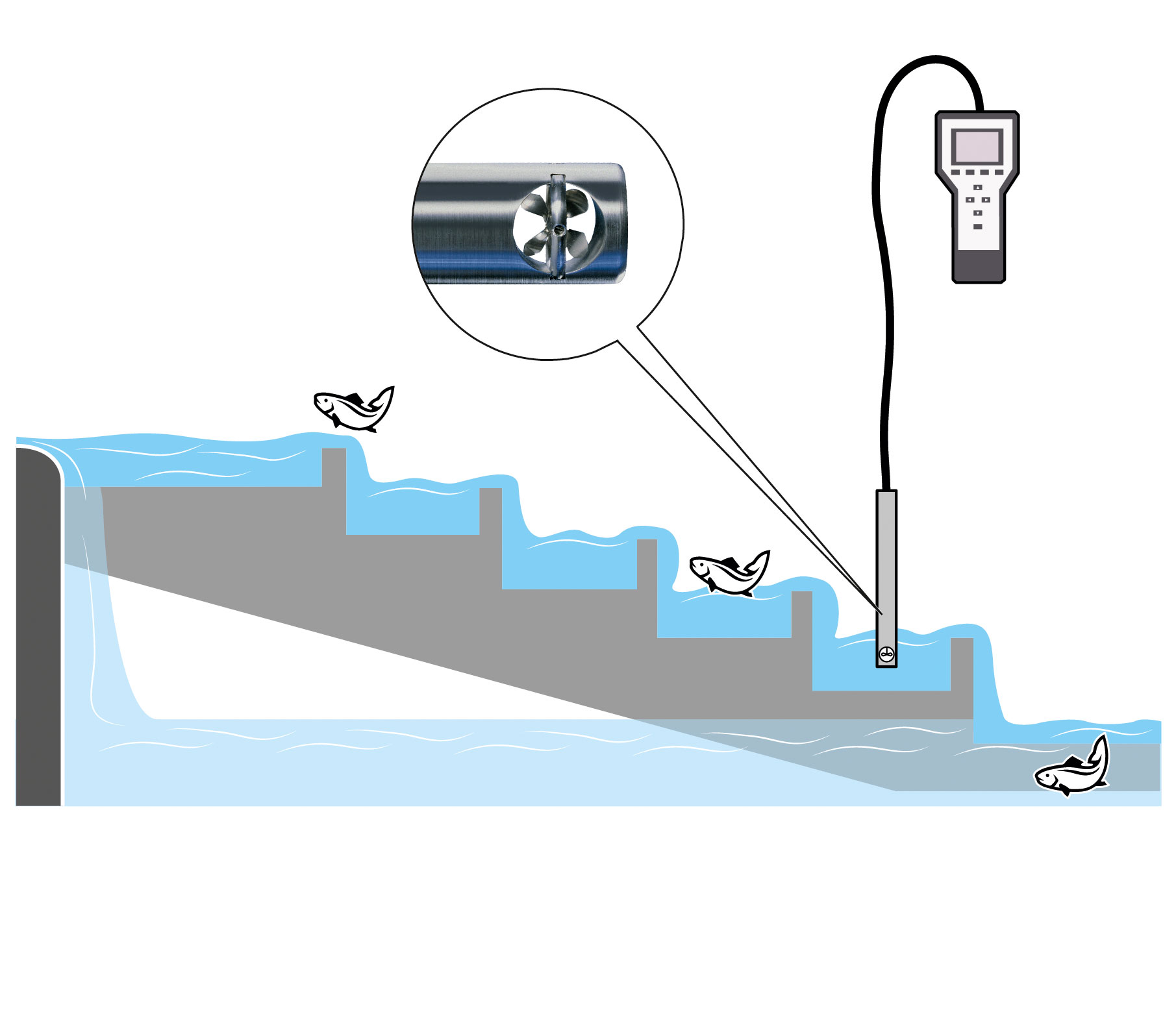

Flow measurement in flowing waters

Visualising rotational flow in gas flow for studies, teaching and practice

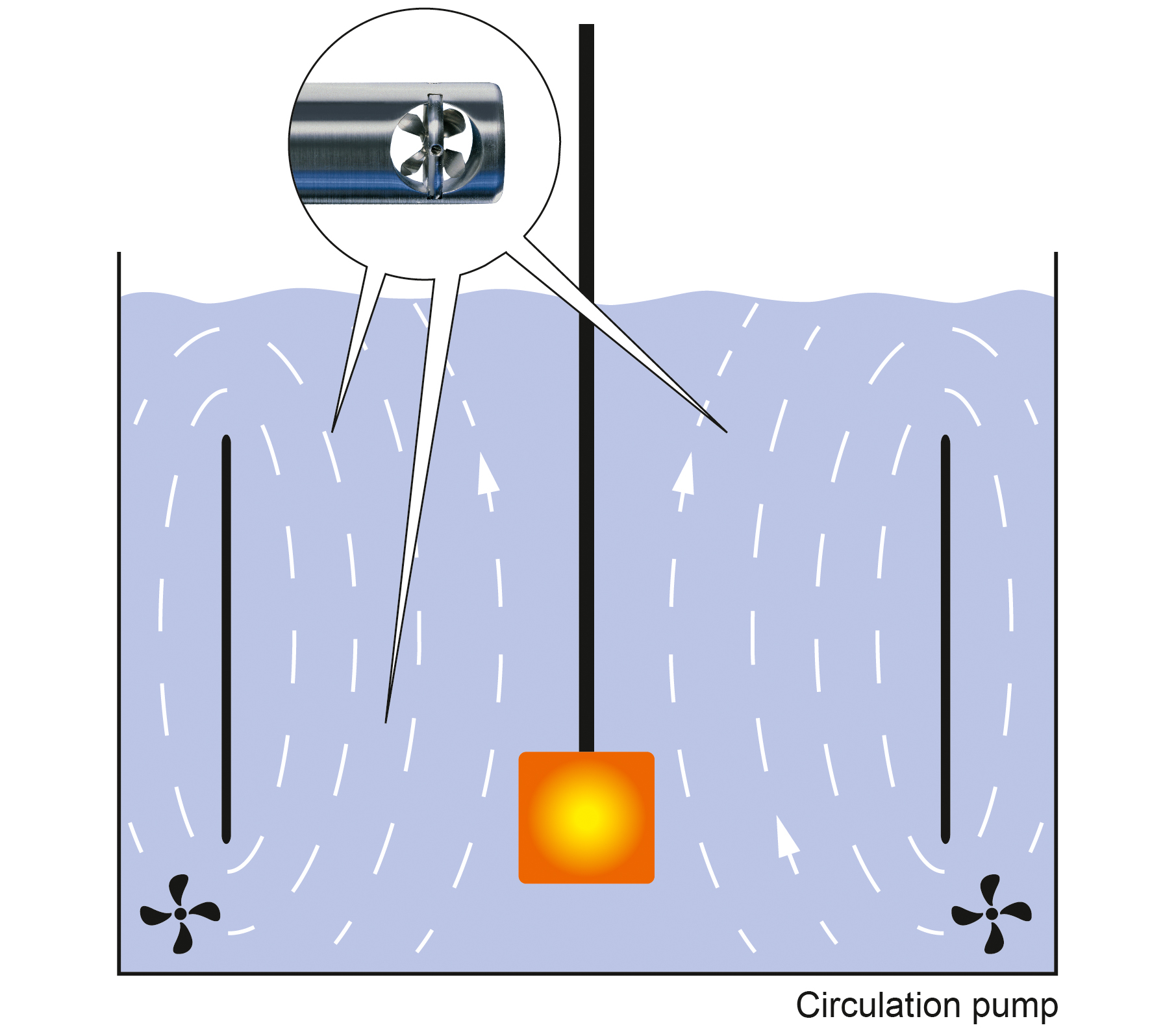

Flow measurement in Quenching basin in hardening plants

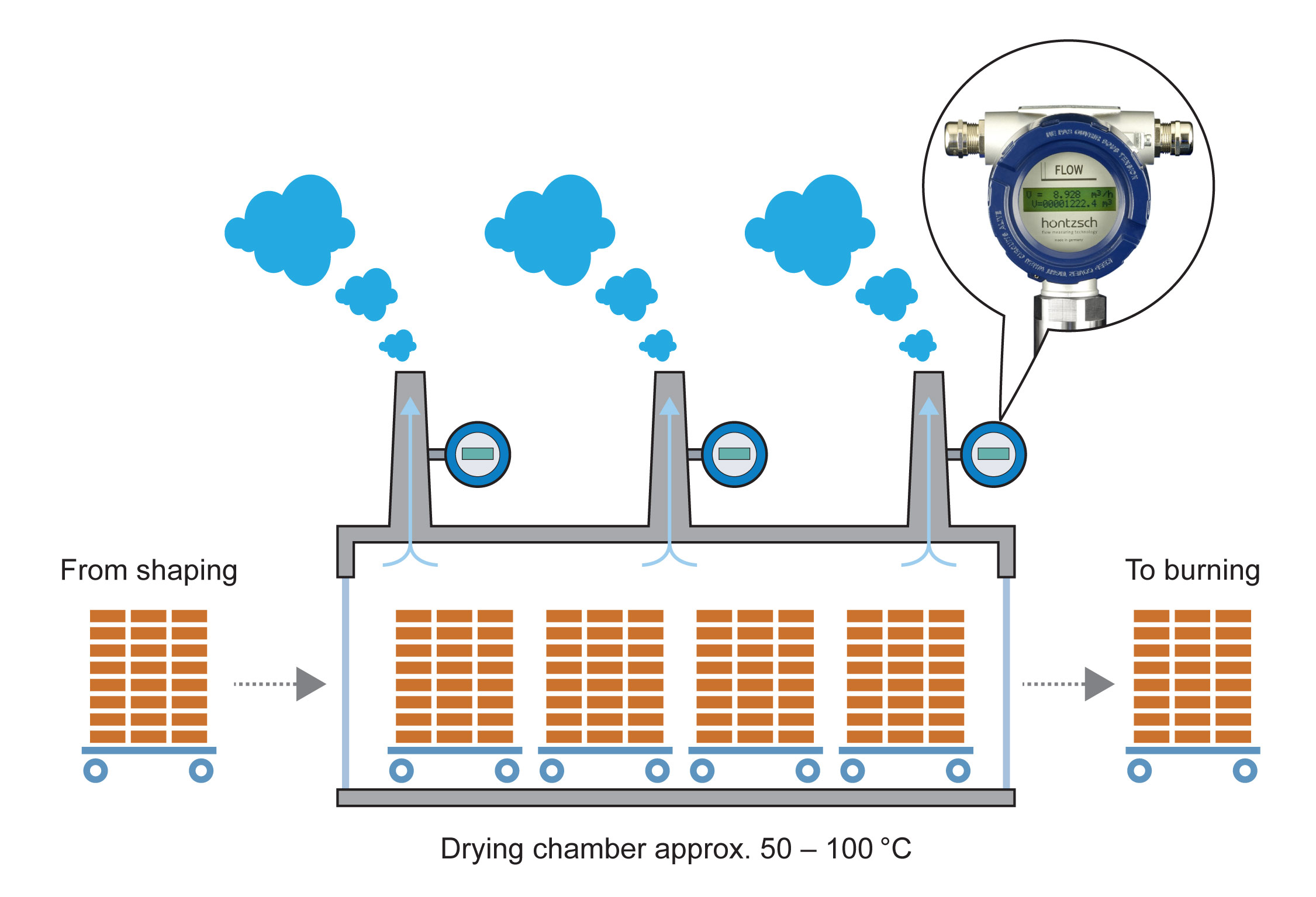

Flow measurement in a brick factory when drying bricks

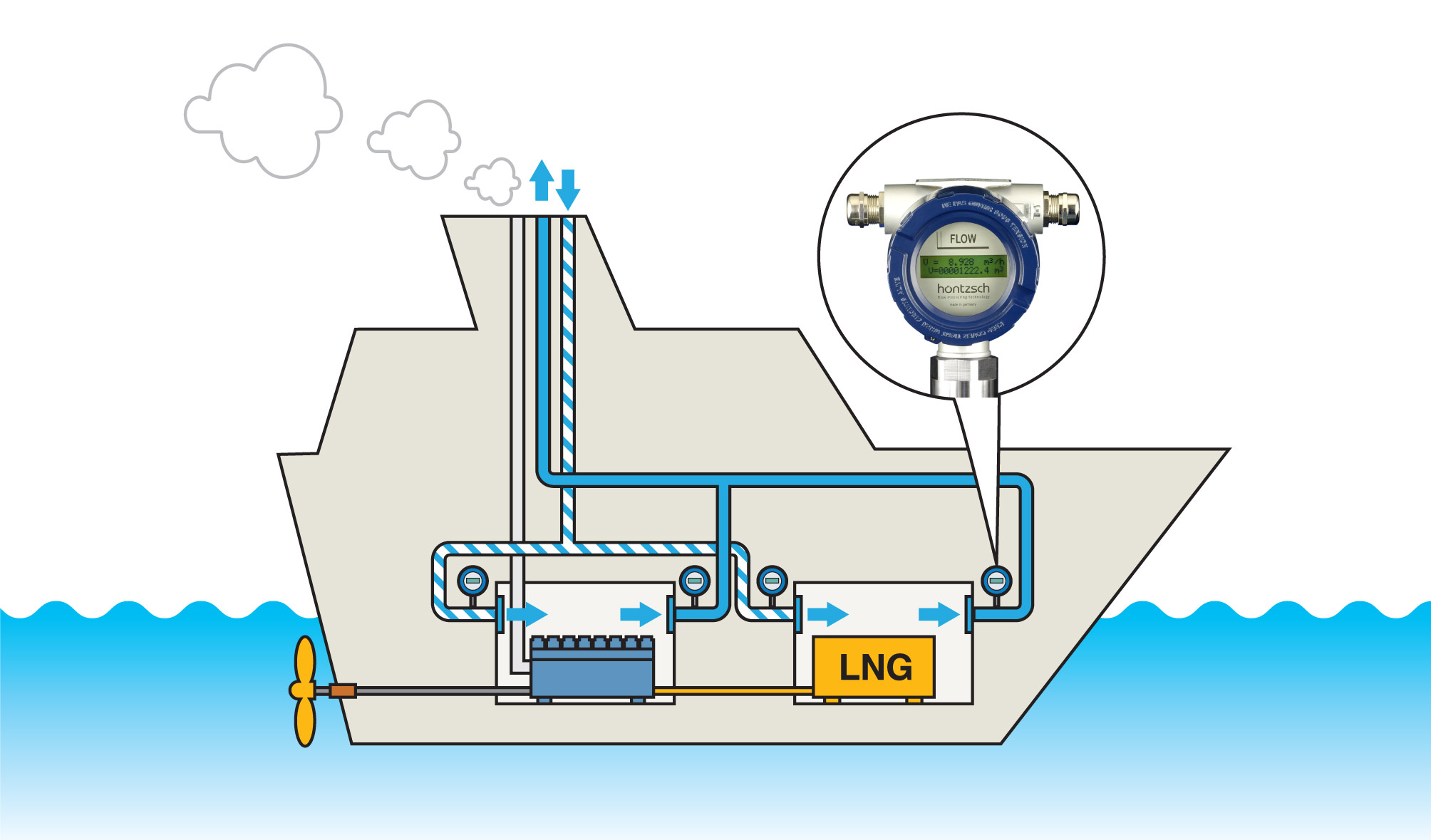

Monitoring ventilation on LNG ships

Flow condition in the 3D printer housing

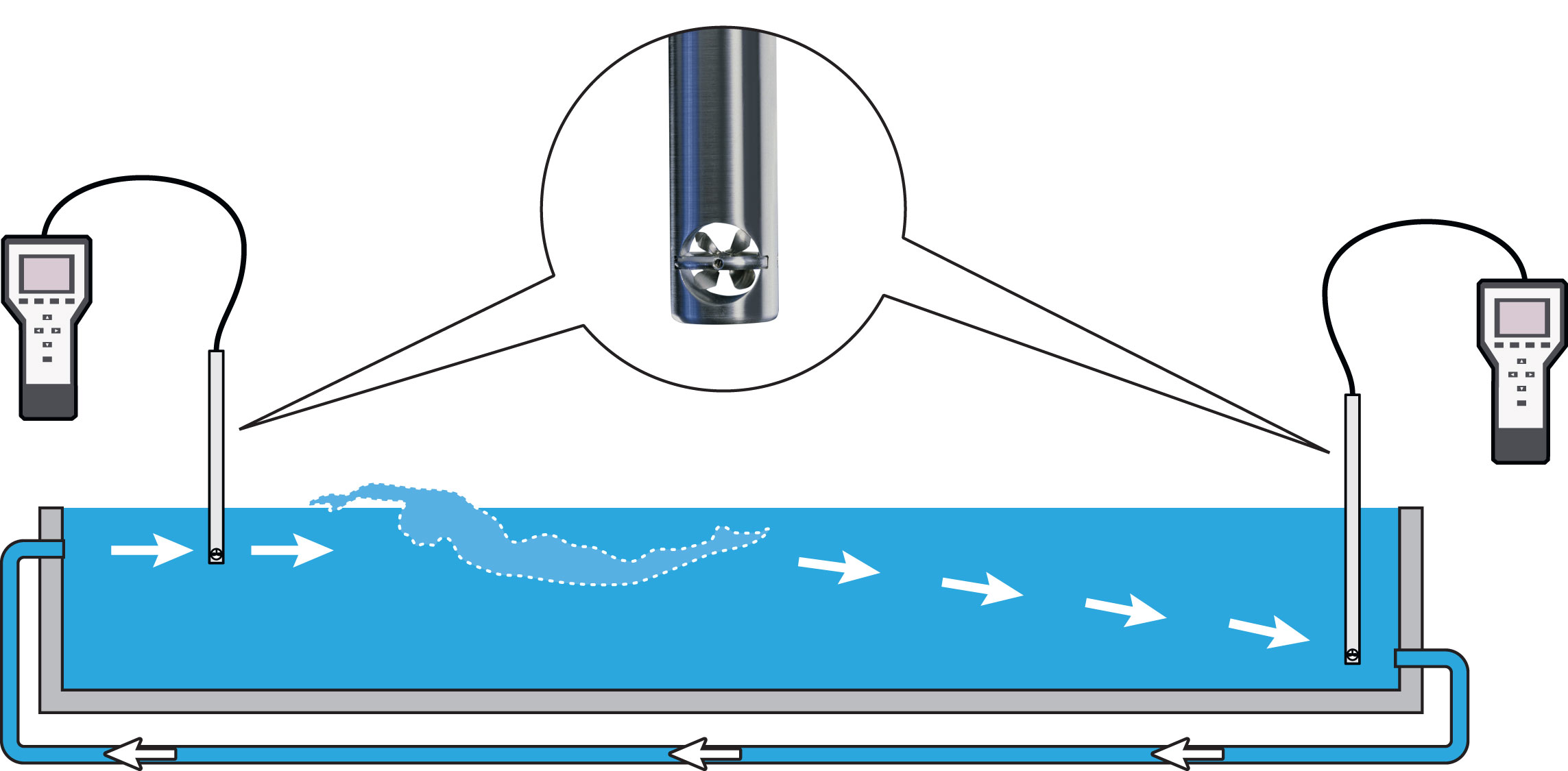

Measuring flow velocity in (swimming) pools

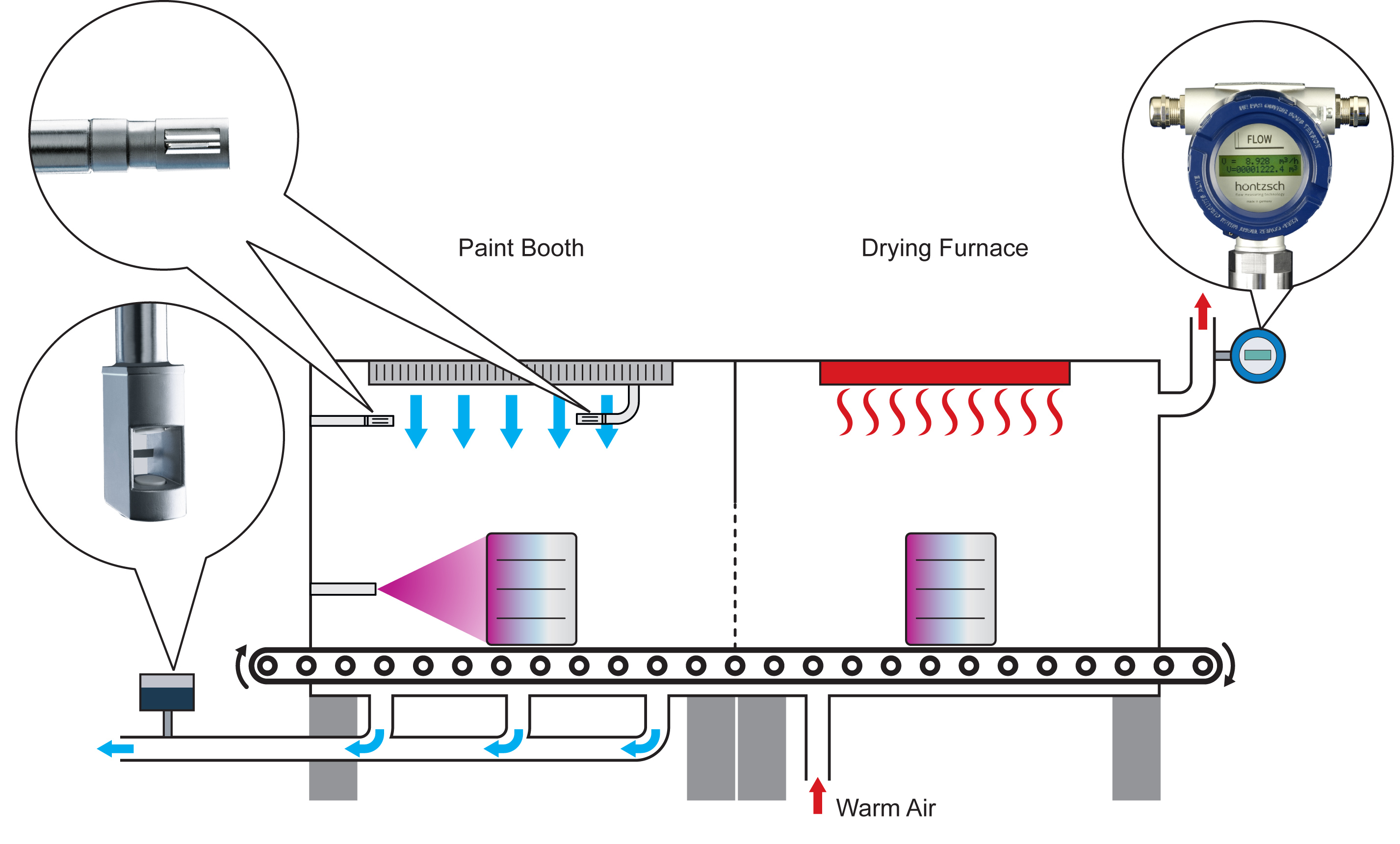

Flow measurement in coating facilities

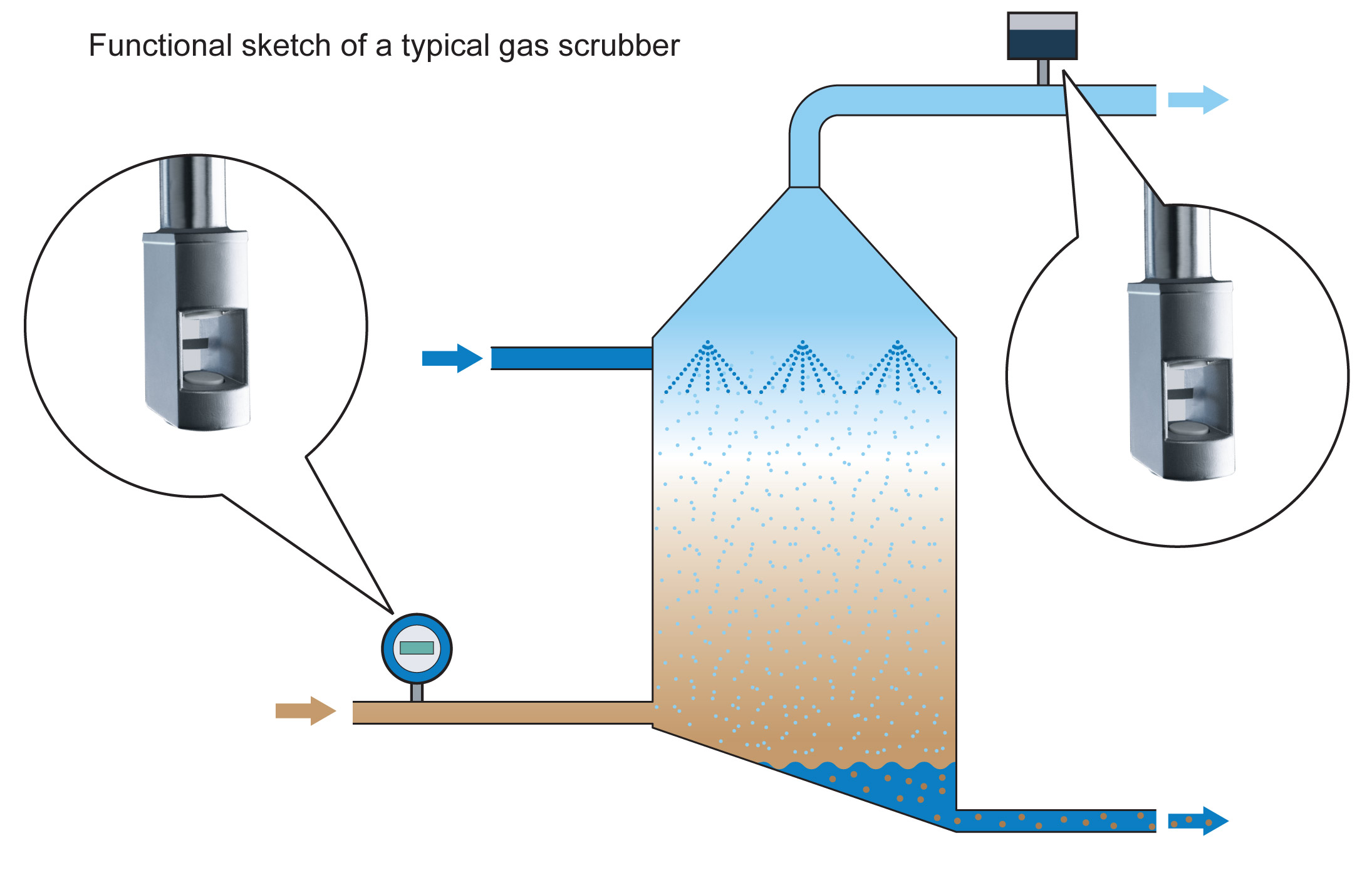

Flow rate measurement at gas scrubbers

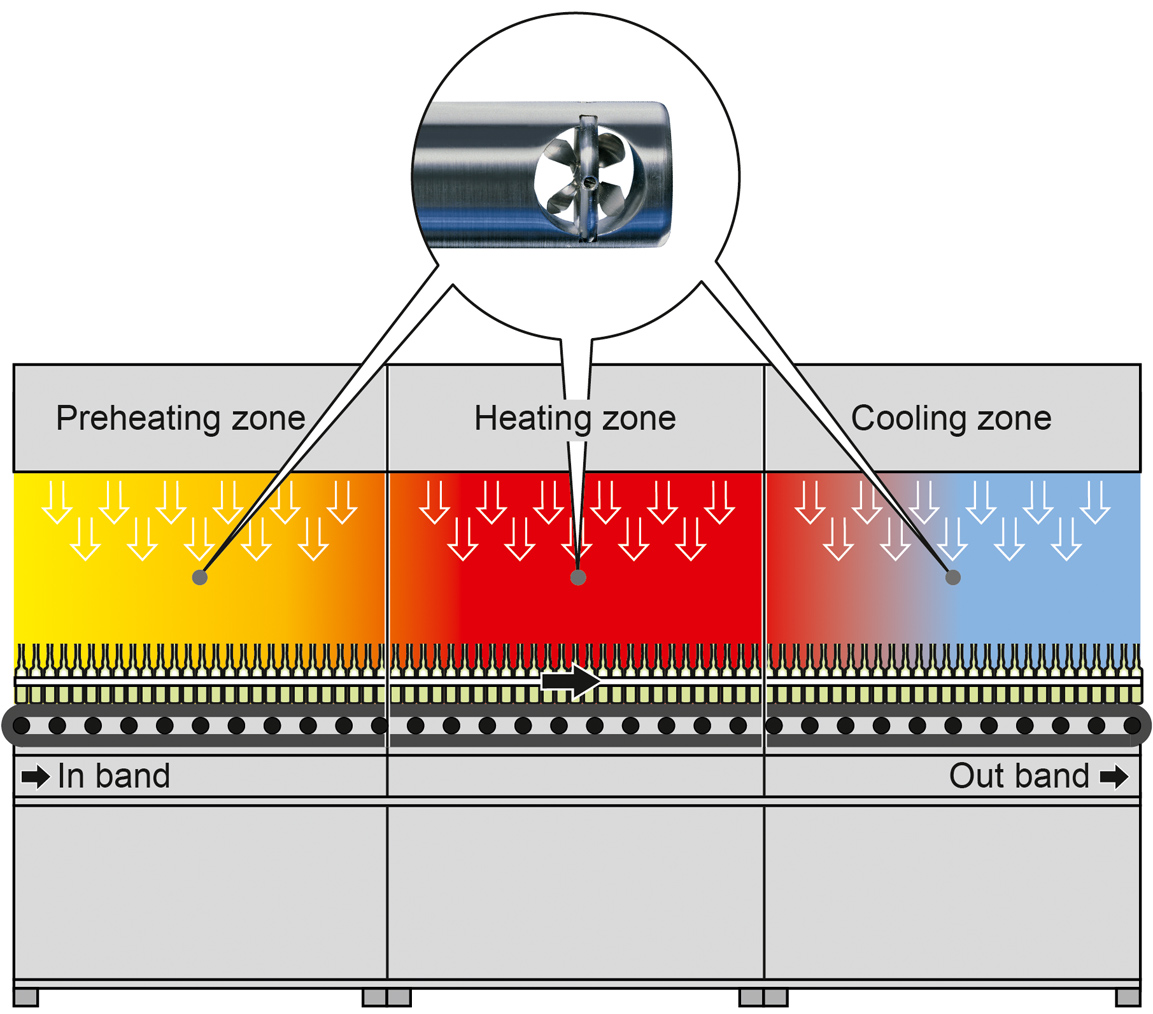

Exhaust air measurement hardening furnaces

flow measurement of blast furnace gas in the steelworks

Shaft and landfill facilities, traffic tunnels, mine tunnels, final disposal sites