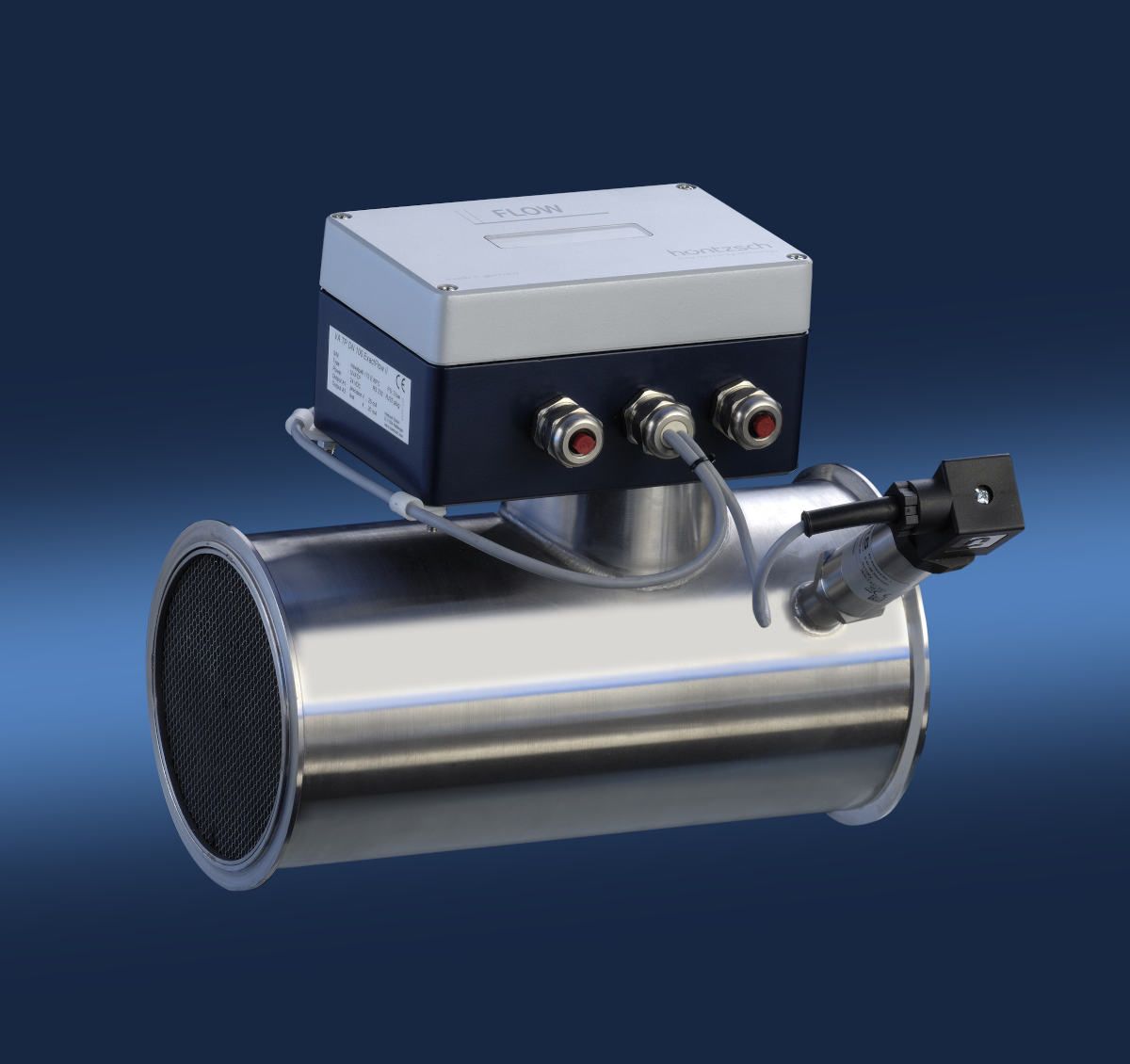

Vortex measuring instrument for flow rate and Flow velocity in air and gases

Vortex VA

Flow rate and flow velocity measurement in wet and/or particulate-laden gases, biogas or exhaust gas, also according to Clean Air Guidelines, (TA Luft). Flow rate measurement of sludge aeration air, sewage gas, landfill gas, water vapour and engine intake air on test stations. Flow velocity in climatic wind tunnels, diluted car exhaust gas, traffic tunnels and in nuclear reactor technology.

also for wet, particle-laden gases.

Offer higher flexibility when used in pipes and ducts with larger diameters or in portable applications.

Read more

provide almost negligible measurement uncertainty when used in small pipe diameters.

Read more

for fixed evaluation of vortex probes VA and measuring tubes VA Di.

Read more

for portable applications with VA probes

Read more

PC software for downlaoding data from handheld units or configuring evaluation units, isolation / supply units ...

Read moreHöntzsch vortex meter: Vortex flow sensor

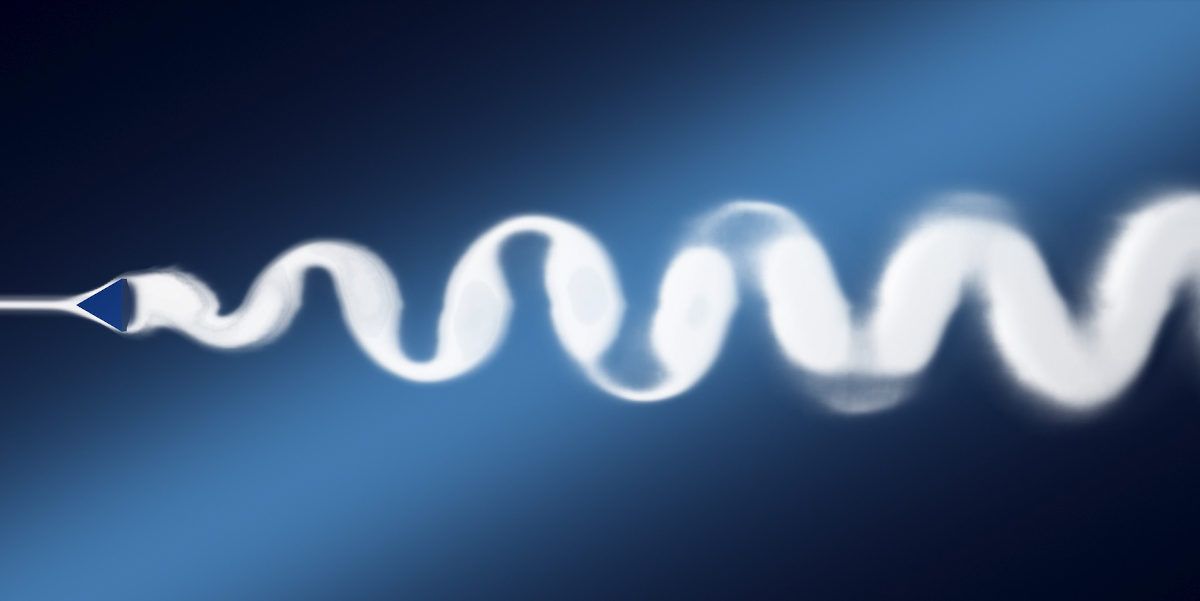

How does a vortex flow measuring instrument work?

Derived from the Kármán phenomenon of vortex shedding, this principle of measurement is based on vortices forming around a bluff body in the sensor head. Their shedding frequency is detected with the help of an ultrasonic field, thus allowing for precise measurement of flow velocity and flow rate, from just 0.5 m/s, of air/gases.

What are the advantages compared to other flow measuring sensors?

Flow rate measurements are to a large extent unaffected by changes in pressure, temperature, kinematic viscosity and gas composition. The great advantages of ultrasonic scanning of the flow velocity are the very low initial value of just 0.5 m/s and the wide measuring range!

Vortex meters have high long-term stability, no moving parts and are resistant to aggressive gases. They still deliver exact results even when the flow is particle-laden or condensate forms. This means that vortex flowmeters are highly suited for biogas measurement or flow rate measurement in exhaust emissions. They deliver exact measuring results even in change of gas composition, particle laden flow or condensate formation.

Sensing of rotational direction and with it recognition of the +/- direction of flow.

For which industries is the vortex sensor suited?

The range of applications for Höntzsch vortex flow meters is manifold. For example, the ex-protected (ATEX, CSA) vortex sensor is ideally suited for flow rate measurement in biogas, sewage gas and landfill gas. Through the process-related, partially low gas onset, the lowest flow velocities can be measured with our vortex meters, making them an excellent choice for biogas, sewage and landfill gas measurement . Furthermore, the gas composition or changes in the gas, as well as wet or particle-laden gas, have no effect on the measuring results. The optimized design of the flow sensor causes a negligible pressure loss when measuring volume flow, so that even critical processes and applications as well as normative guidelines can be adhered to. These features distinguish us from other providers of conventional vortex flowmetes.

Most common fields of application are for example:

- Explosion-proof measuring of flow rate in biogas, sewage gas, landfill gas

- Critical processes and applications in the chemical industry or petrochemistry

- portable and fixed measurements in aggressive and explosive process gases, flare gas and exhaust gas

- Dust laden and hot gases for example in burner control units of rotary kiln in the cement industry or filtration of exhaust gas

- Flow measurement of engine intake air in engine test benches

- Flow measurement in traffic tunnels, mining and waste disposal sites

- Safety relevant applications up to SIL 3

- Measurements in ventilation and aeration, VOC-plants

- Measurements in exhaust gas/contaminated air

- Measurements in thermal incineration plants, exhaust air cleaning plants RTO/RNV, regenrative post-combustion..

- Flow measurement of sludge aeration air

- Measurement in overheated water vapour

- Flow measurement in climatic wind tunnels

- In nuclear reactor technology

- In CVS systems

- Waste incineration plants

|  |

Design and most important features of our vortex sensor

- vortex insertion probes for installation in pipelines with ID from 80 mm

- vortex measuring tubes with ID from 25 mm

- combined sensors for flow and temperature

- vortex sensors for flow measurement in gases

- for applications in condensate or particle-laden, aggressive gases (biogas measurement)

- vortex meters have no moving parts

- for flow rate measurement in accordance with TA Luft

- SIL2/SC3 certification / Performance Level

- marginal pressure loss

- for application in explosive atmospheres (ATEX, CSA)

- large turndown

- corrosion-resistant designs