Process data

Measuring task:

Flow velocity for the gas scrubber’s process control

Measuring point:

Polluted exhaust air before gas scrubbing; humid and condensing air

Measuring range:

Usually up to 20 m/s

Process pressure:

Atmospheric

Process environment:

Usually ambient temperature up to 100 °C

Recommended products

Vortex insertion probe

For the use in aggressive media:

Vortex Probe VA40 ZG10 ProductProduct data sheet

Vortex Probe VA40 ZG4productproduct data sheet

For the use in humid air:

Vortex Probe VA40 ZG7

Productproduct data sheet

Application

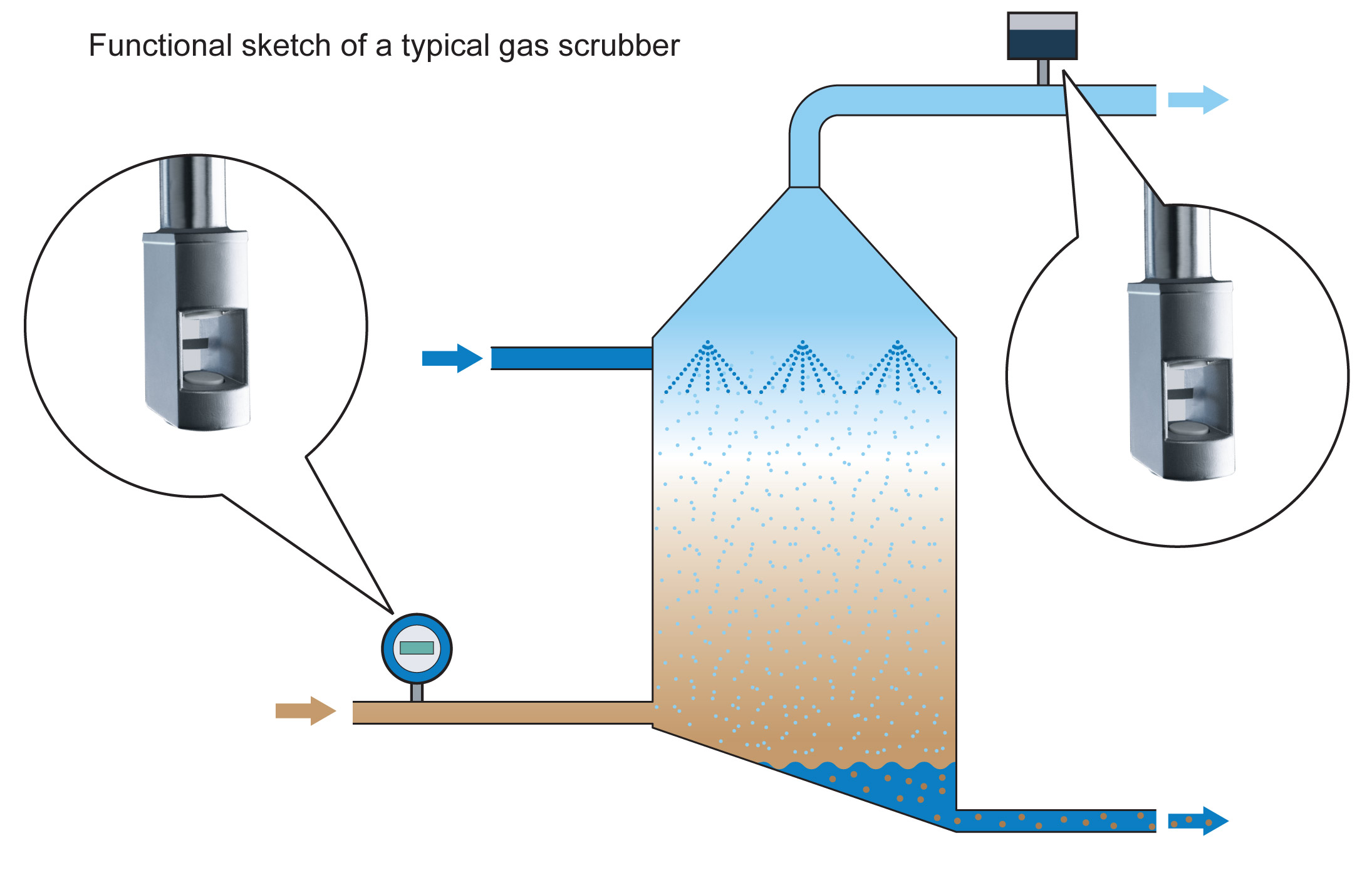

Many production processes result in exhaust air with hazardous components such as chloride or sulphur. It has to be cleaned before it’s released into the environment. One way to clean it is with the help of a gas scrubber, where the exhaust air is „scrubbed“ from the pollution. Before it gets to the gas scrubber the polluted air and afterwards the clean but moisture saturated air must be measured.

Your advantage

Safe

The process is controlled and secured through the measurement; around the clock!

Robust

Our sensors are perfectly suited for the use in aggressive gas mixtures or humid and condensing gases