More info on gas recovery of fuel and bitumen

VOC - volatile organic compounds describes gaseous and vaporous substances of organic origin in ambient air. For example hydrocarbon, alcohol, aldehyde and organic acid. VOCs can occur while processing dissolvent, paint, glue, liquid fuel and many other organic compounds and possibly be released into the environment.

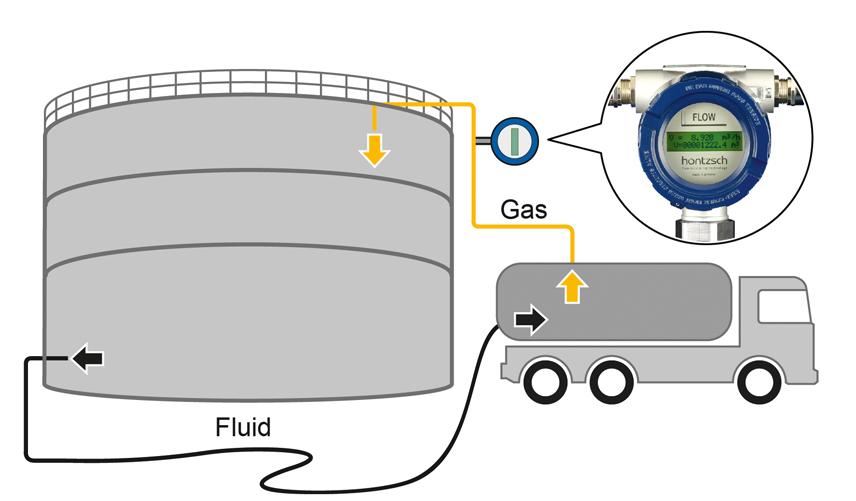

VOCs can be quite health damaging in closed rooms. That’s why emissions are legally limited and the limit value has been tightened several times. A possible source for VOC emissions is while fueling tank wagons, road tankers or oil tankers. The same risk arises while fueling tank farms with gasoline in refineries or storages and at gas stations. Regulations to limit VOC emissions during decanting and storing automotive gas, fuel mixtures or straight-run gasoline regulate the refueling process. To collect the suppressed gas from the target storage it‘s actively sucked and thanks to the recovery refed to recycling. Flow rate is measured during this process for safety reasons and to calculate efficiency which led Germany to greatly decrease its VOC emission.

Why is recovery gas flow measured?

Measuring backflowing gas and comparing it to the inflowing fuel can help recognise a leak in refineries and therefore also increase the tank farm’s safety. The measurement also helps showing how much of the gas mixture is fed to gas recovery. That way the extent of gas recovery and the facility’s efficiency can be determined. Without those measures, VOC emissions from fuelling processes with automotive gas alone would still be at close to 100,000 t/a instead of the current 2,500 t/a.

What are the special features of measuring gas recovery?

Measuring gas recovery is quite challenging since the recovery gas can contain condensate and pollution. These unwanted components can cause measuring errors or in the worst case a complete fail of the measuring system.

Without any moving parts our vortex sensor is qualified for the measurement in gas displacement systems. For many decades the vortex sensors have proven themselves worthy in gas displacement and in refineries.

Petrol vapour and air can form an explosive mixture, which is why fuelling areas are often classified as ex-zones. No problem: these vortex sensors are available for the use up to ex-zone 0/1, also in pressure-capsulated versions. Recovery gas measurements are almost exlusively relevant for safety issues, therefore demanding highest standards regarding the measuring equipment. Vortex sensors have no moving parts and based on their measuring principle they are perfectly suited for this task. On top of that they’re also SIL2 certified.

Where can you find gas displacements?

While reloading bitumen, gas is being recovered and measured. The pictures below show how dirty the sensor gets during the process. The recovered gas is strongly contaminated with bitumen residue which can compromise the measurement of the gas displacement. The Höntzsch vortex sensor pictured below is especially suited for such demanding tasks.