Process data

Measuring task:

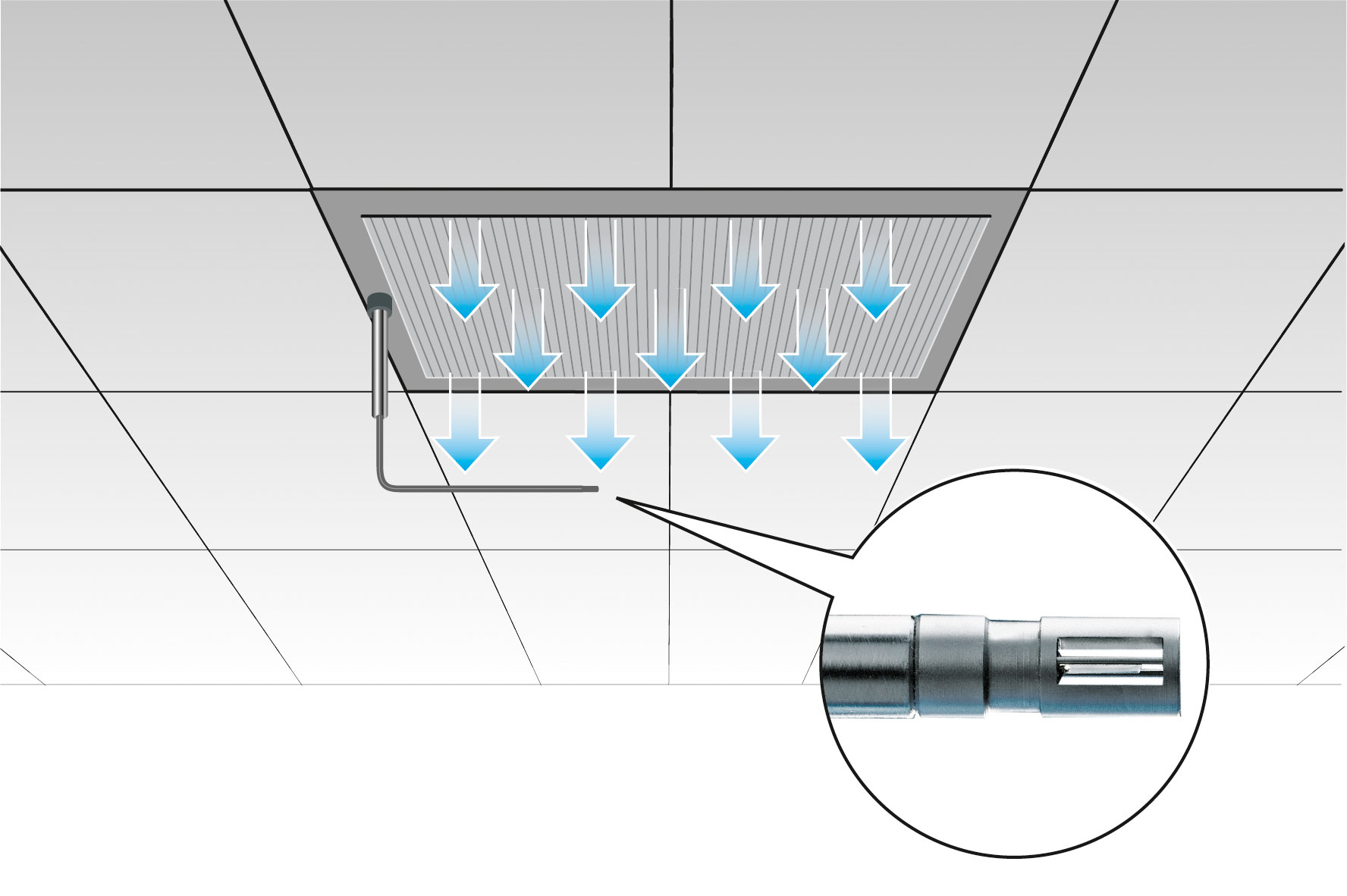

Flow velocity for process regulation

Measuring point:

Where laminar flow exits, below the filter

Measuring range:

Up to 1 m/s

Process pressure:

Atmospheric

Process environment

Typically: +10 .. +30 °C

Your advantage

Safe

The process is regulated and secured by measuring the laminar flow – around the clock!

Compact

Laminar flow sensors with an integrated transducer and mounting components

Sterilisable

With hydrogen peroxide, formaldehyde or alcohols

Application

In laminar flow, air is directed from top to bottom through targeted ventilation. Due to the low flow velocity there’s no cross flow meaning that the laminar flow’s single flow streams stay separated from each other. These low in turbulence laminar flows are necessary to ensure the required air exchange in clean rooms or glove boxes. It’s important that the laminar flow doesn’t cause a stir of small dust particles. Therefore flow velocity in process integrated air conditioners has to be quite low. Laminar flow is also required in other applications such as paint booths or ventilation in buildings. It has been relevant in the area of workplace ventilation and safety long before Corona. Clean rooms are important in medical-pharmaceutical and biotechnological fields to create controllable and therefore replicable environmental conditions. Optimally regulated air conditioners play a significant role in surgery rooms. Other areas that require replicable clean room conditions are electronics and wafer productions as well as many laboratories in basic research and material research. Special applications in the packaging industry also require clean room conditions that are unimaginable without the right sensor technology to monitor and regulate the installed air conditioners.