Process data

Measuring task:

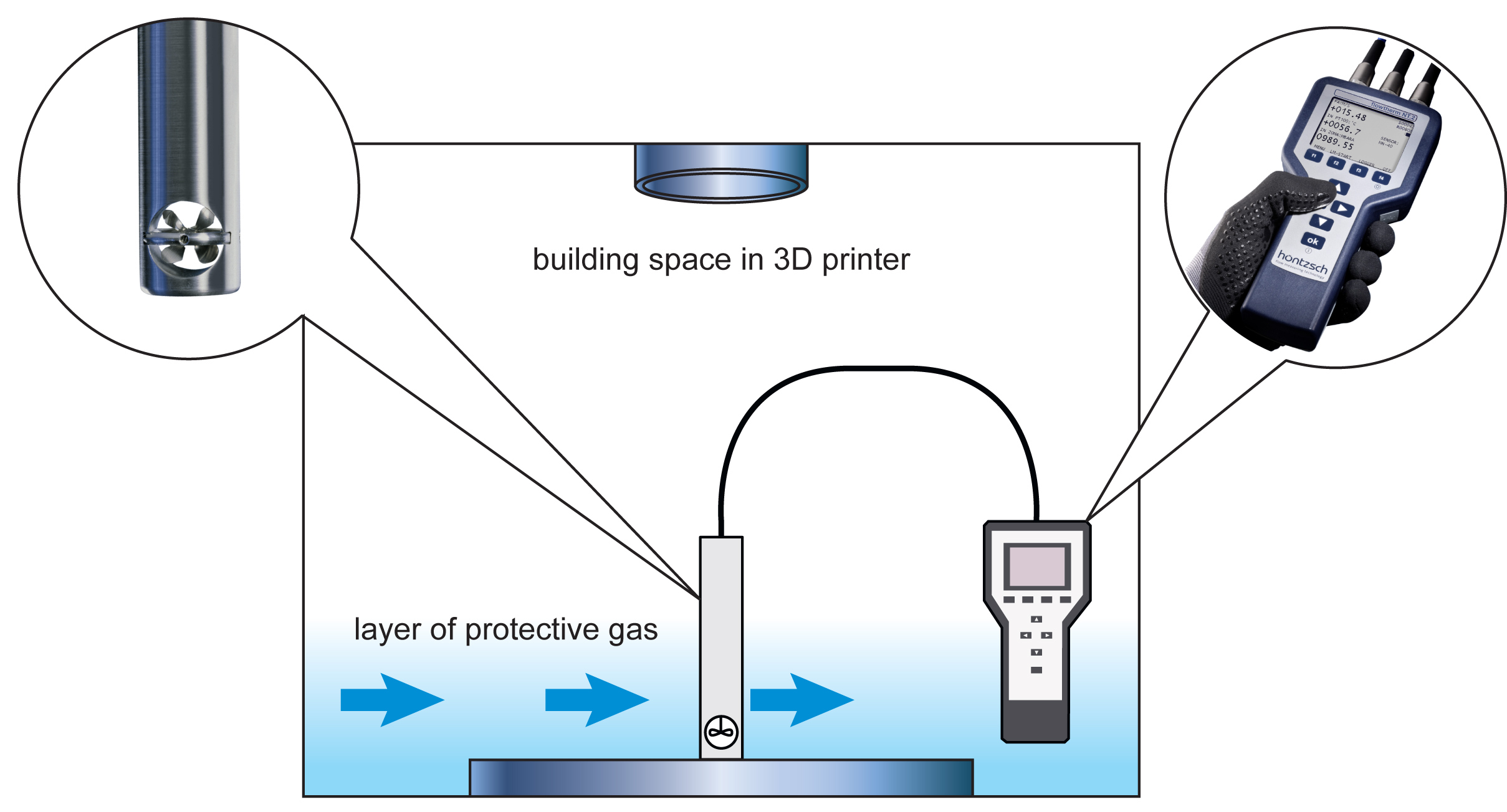

Recording flow velocity in building spaces of 3D printers

Measuring point:

Oncoming flow with different gases with different gas composition and density

Measuring range:

Mostly 1 – 3 m/s and lower

Process pressure:

Atmospheric

Process environment:

Measurements in development in clean machines / 3D printers

Recommended products

Vane wheel anemometer ZS25, ZS30

Vane wheel anemometer TS/TSR

Handheld flowtherm NT.2

Application

Measuring flow velocities in building spaces of 3D printers to determine regularity of flow. At a manufacturer of industrial gases, metal powder 3D printers from various manufacturers are being used to determine inflow conditions and regularity of the horizontal gas flow across the construction panel. This is important to transport the resulting gases and spray that result when melting different metal powders. An even flow and sufficient flow velocity is essential. These measurements can also be used in machines with other applications that come from Rapid Prototyping such as Stereolithographie (SLA), selective laser melting (SLM), selective laser sintering (SLS) etc.

Your advantage

Safe

Safe and fast determination of flow velocity with directional flow sensing

Ergonomic

Handheld unit with data logger and average determination, illuminated display to read data

Unique

Starting values of vane wheel sensors at 0.2 m/s in air. Application in other gases such as argon, nitrogen, helium, … also available in versions for small building spaces.

ATEX version for zone 1 possible.