Process data

Measuring task:

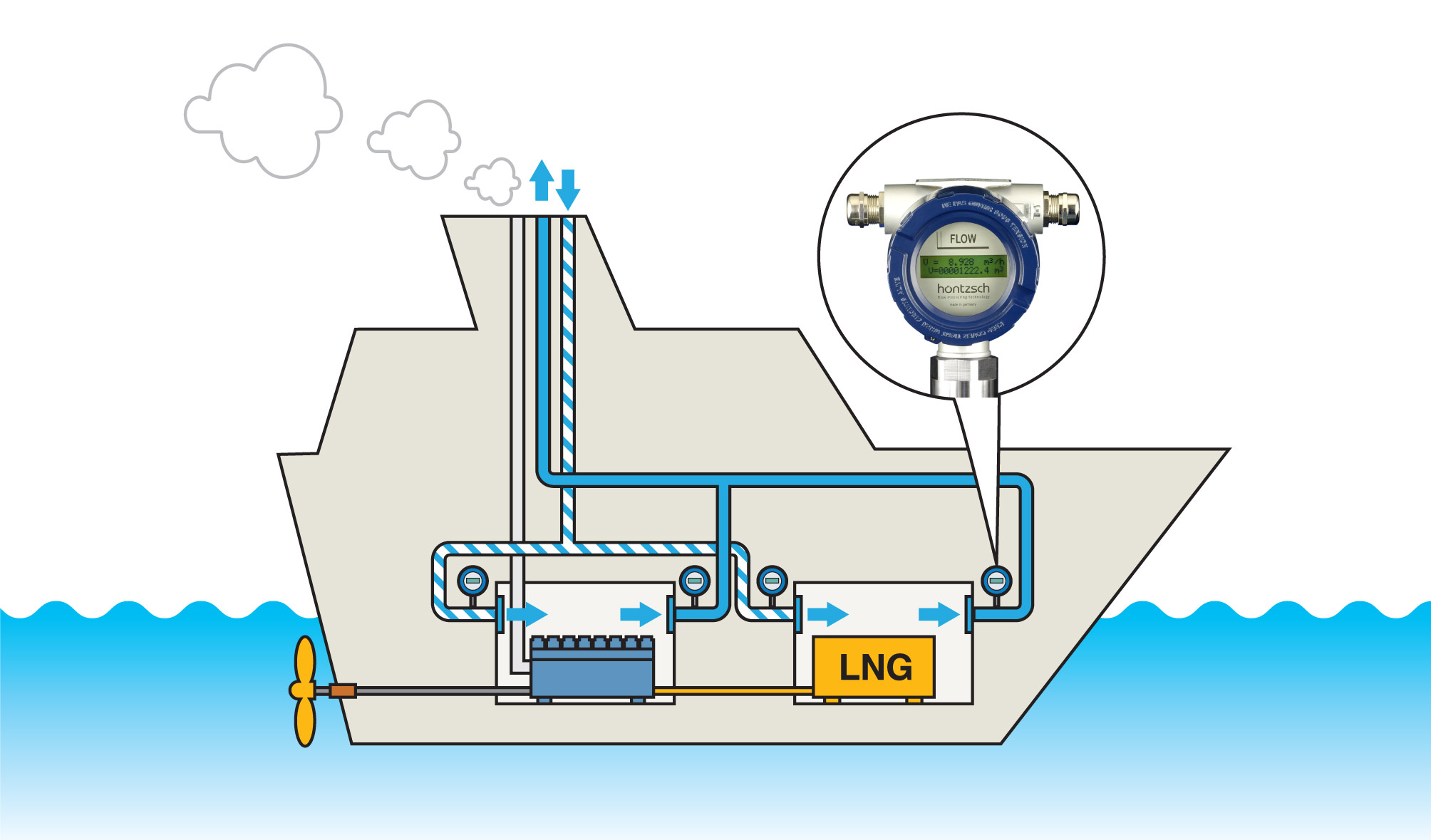

Monitoring forced ventilation on LNG ships

Measuring point:

In ventilation pipes

Measuring range:

0.5 … 20 m/s

Process pressure:

Atmospheric

Process environment

Typically ATEX zone

salty sea air

partly SIL2 required

dislocation due to motion of sea

Your advantage

Safe

The adherence to the required gas exchange is monitored by the measurement

Reliable

With these Höntzsch sensors you can measure permantently and safely all the time

ATEX-accreditation

The sensors are also available for the use in ATEX zones up to 0/1

Unique

Special robust design with no moving parts

Application

According to the International Maritime Organisation IMO the limit of sulfur in fuels was considerably limited in 2020, making the sulfur-free fuel LNG (liquified natural gas) more significant. The first big cruise ships are equipped with future technology powered with LNG. The use of LNG instead of commonly used fuel oil lowers emissions remarkably without having to use an additional, expensive exhaust gas purification system (so called scrubber). Ships powered with LNG not only reduce the emission of sulfur oxide entirely but also of nitrogen oxide and fine dust. LNG ships also reduce carbon dioxide emissions. To ensure safe operation of the environmentally friendly LNG drive it’s required to monitor ventilation of the engine rooms. A so called forced ventilation must be a given. Controlled engine room ventilation prevents the rise of potentially dangerous atmospheres. The harsh environment at sea demands high standards from the sensor technology which limits the functionality of many measuring principles. Höntzsch vortex sensors are perfectly suited for monitoring forced ventilation and they’re already tested in use at sea.

Recommended products

Vortex flow sensor VA40 … ZG8 Ex-d / ATEX

Vortex flow sensor VA DI ZG1 Ex-d