Process data

Measuring task:

To increase the plant’s energy efficiency flow velocity should be measured in order to calculate (mass) flow rate.

Measuring point:

Supply pipe leading to the aeration basins or in every ventilation pipe towards the basins

Measuring range:

Low m³/h up to higher than 10,000 m³/h depending on the measuring point and pipeline

Pipelines from DN 32 and smaller up to DN 1000 and larger

Process pressure

Usually 0.4 – 0.6 bar overpressure

Process environment:

Normally in non explosive areas as outdoor installations or in the plant’s engineering room

Application

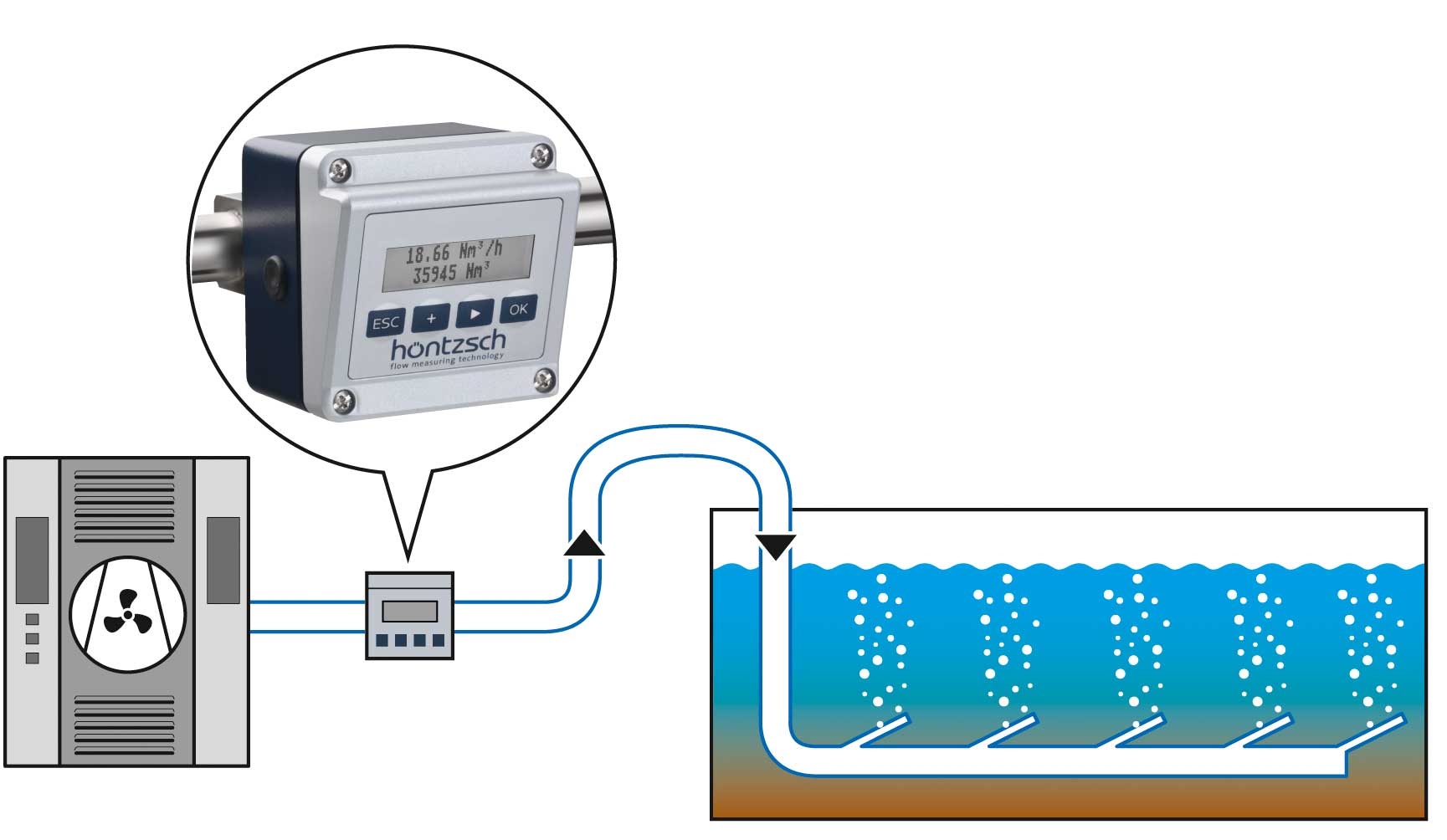

Many municipal sewage plants apply the activated sludge process where sludge aeration air is being pumped into aeration basins, speeding up the degradation process.

Large compressors ensure sufficient sludge aeration air in the basins which requires a lot of energy. Generating sludge aeration air makes up the majority of the sewage plant‘s electricity requirement causing a significant power requirement in the municipality and therefore it has the greatest potential for energy saving.

The demand for sludge areation air depends on the level of pollution and the amount of water in the aeration basins. Said demand can be regulated by measuring the actual flow rate. The measurement increases the plant’s energy efficiency in combination with a corresponding compressor control.

Your advantage

Safe

Safe, fast measurement under all weather conditions

Economical

Installation via ½“ bushing optionally with a ball valve

Data transmission:

Two analog outputs 4-20 mA for flow rate/mass flow/flow velocity and temperature as well as a digital output as the limit value or counter

Recommended products

Thermal flow sensor TA10

Thermal flow sensor TADi